|

It appears we may be in for a snowy winter. As I am writing this column, Buffalo, N.Y. is digging out from 5 to 7 feet of snow. Besides the potential for collapsing a greenhouse, light levels are considerably reduced with snow on the roof. Questions I frequently receive include: How much heat does it take and what are the best methods to remove snow? Weighing the benefits of snow meltingTo change snow from its solid form to liquid water so it can drain off requires 144 Btu/lb. The weight of snow can vary considerably depending on whether it is a wet snow or dry snow. A wet snow can be as much as four times heavier than dry snow. Wet snows are usually found along coastlines or large bodies of water where moisture is picked up and then cooled and dumped as snow over adjacent land areas. Dry snow is normally found over interior sections of the country. Turn up the heat: what it takes to melt snowLet’s look at an example: 3 inches of wet snow or 12 inches of dry snow is approximately equivalent to 1 inch of water when melted. One inch of water equivalent snow over a square foot weighs 5.2 pounds, multiplied by 144 Btu/pound = 750 Btu’s needed to melt it. Converting it to a snowfall rate, dry snow falling at a rate of 1 inch/hour requires 62 Btu/hr. and a wet snow falling at the same rate requires 250 Btu/hr. To handle a 1-inch wet snowfall rate on the roof of a 30 foot x 100 foot greenhouse requires about 750,000 Btu/hr., much more than is usually installed. Frequently snowfall exceeds the 1 incher/hr. rate. The Buffalo rate was reported to be more than 4 inches/hr at times during the storm. As you can see, it takes considerable heat to get rid of the snow that piles up on a greenhouse roof. Heat transfer through the glazing, air temperature, wind, cloud cover and local site conditions are other variables that influence the melting rate. In addition, evaporation after the snow melts requires additional heat.

Greenhouse snow melting methodsThe typical method for melting the snow on a greenhouse is to open the energy blanket and turn the heat up before the storm starts. This warms the glazing so the snow melts on contact. If it snows faster than the rate that it melts, snow will start to build up. As snow is a good insulator, this creates an insulation barrier reducing the heat loss and allowing the snow to be changed to water that can run off. The problem with melting snow with the heat in a double poly-covered greenhouse is that the double glazing reduces heat loss by about one-third as compared to single glazing. This slows the heat transfer and the rate that the snow can be melted. Reducing air pressure will allow it to deflate to a single layer, but if it is windy, the rippling of the poly puts more stress on the plastic attachments. Some growers use snow rakes to pull the snow off but care should be taken that the snow doesn’t build up too high along the sidewall and crush it in. Bridging is another problem. Snow often slides toward the gutter in ridge and furrow houses. When heated, the snow nearest the gutter melts and runs off, leaving a hollow area underneath. Frequently there is not enough heat to allow the remaining snow to collapse and slide down. Most recommendations are to place heat pipes or distribution tubing under the gutter to melt the snow. Moving these sideways, about 18 inches from the gutter, may help to provide the heat where the bridge normally forms, allowing it to collapse. Placing the heat pipes on a separate manual control allows this zone to be used only when snow is in the forecast. Electric heating cables or hot water piping placed in the gutter have limited effect as their heat output is small and concentrated in a very small area. There is also considerable heat loss through the metal gutter. Usually they create a tunnel in the snow and prevent additional snow from sliding into the gutter. A plan should be developed before the storm starts. Frequent checks on the snow build-up and the operation of the heating equipment are important.

Bartok is a regular contributor to Greenhouse Management and an agricultural engineer and emeritus extension professor at the University of Connecticut. He is an author, consultant and a certified technical service provider doing greenhouse energy audits for USDA grant programs in New England. Have a question? You can write John at jbartok@rcn.com.

|

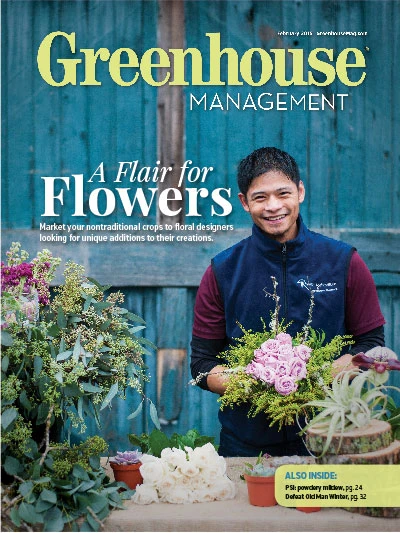

Explore the February 2015 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Leading women of Greenhouse Management

- Showing up at your horticulture business as your whole self

- Leading Women of Horticulture: Katie Dubow, Garden Media Group, and Aubry Field, Lizzy Blossom

- USDA fires experts on invasive pests, including Asian citrus psyllid, chilli thrips

- Farwest Show calls for 2025 New Varieties Showcase entries

- Leading Women of Horticulture: Arden Pontasch, North Creek Nurseries

- Leading Women of Horticulture: Emily Showalter, Willoway Nurseries

- Leading Women of Horticulture: Anna Ball, Ball Hort, and Terri McEnaney, Bailey Nurseries