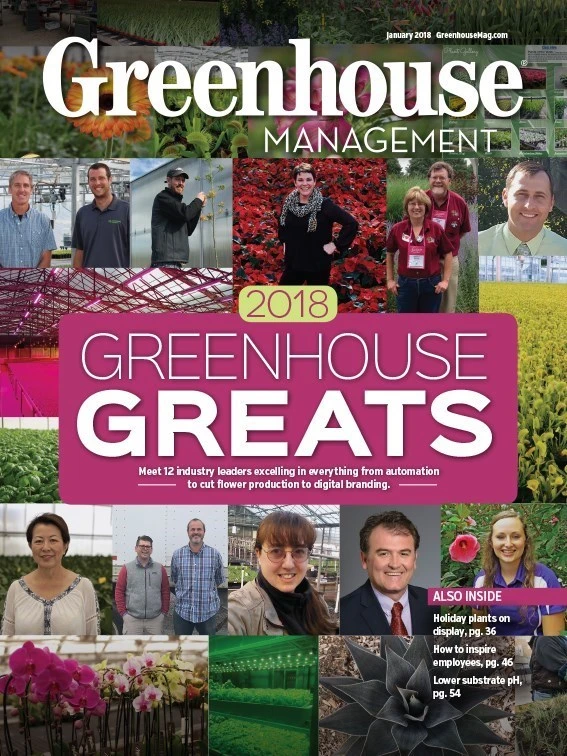

From hybridizing to plant trialing to interning, experienced and emerging professionals are making their mark on the way greenhouses effectively operate. Some have begun to offer floral arrangements as a value-added solution while others use their websites to allow current and prospective customers to navigate their inventory. All have a vision for the future, and they aren’t afraid to execute their plan to make their vision a reality.

For our second annual edition of Greenhouse Greats, Greenhouse Management spoke to a group of these outstanding industry members, who define what it means to be great in the greenhouse industry.

» Automation

Hoffman Nursery, Rougemont, N.C.

WHY THEY’RE GREAT: The Rougemont, N.C.-based grower started utilizing automation processes about 10 years ago, according to project manager David Hoffman. It did so to modernize the business and reduce its reliance on a shrinking labor pool.

“It’s been a driving force for us over the past few years,” says nursery manager Scott Epps. “We are in a pretty competitive area, and labor is always a challenge. Some years, we find enough workers, and some years, we can’t find the labor. We see this as a way to rely on automation to get more done. It’s not to replace labor, but to be there so we don’t need as much labor.”

MANAGING LABOR: For years, Hoffman grew in hoop houses that couldn’t be automated in any way — meaning all labor had to be done by hand. Its first automation efforts beyond structures came in 2007 when they purchased an AgriNomix sticking line. The machine allowed Hoffman to transport plants faster — as they weren’t using it exclusively to stick plants, but also to move plants faster through production. But it took a few years for the business to determine what automation fit its needs the best.

Since then, Hoffman has purchased its first transplanter and upgraded to gutter-connected greenhouses with boom irrigation and an environmental control system. This process automated labor in labor-intensive, growing-related tasks. Currently, the business is finishing a 1.3-acre greenhouse that will be automated.

When it comes to future automation, Hoffman says the nursey will continue to look at the tasks that they are struggling with during the busiest parts of the year. The transplant line installed in 2016, for instance, saved the company from having to pay for hours of labor.

“David just looked at the numbers, and the transplant line saved us 3,700 hours of labor this year,” Epps says. “That is crucial to the success of our business. To some, they look at us today and say that we aren’t automated because we aren’t like Metrolina [Greenhouses] or some other businesses where everything you see is automated. But for us, it was a huge step to go from hoop houses to where we are today. We recognize the benefits of getting better.” — Chris Manning

» Breeder

Hans Hansen,

Walters Gardens,

Zeeland, Mich.

WHY HE’S GREAT: Since he began hybridizing lilies as a teenager in the 1980s, Hans Hansen has introduced plants from many different genera, including Hosta, Hibiscus, Baptisia and Paeonia. As director of new plant development at Walters Gardens, a position he started in 2009, Hansen brought the Baptisia Decadence series — including varieties such as ‘Blueberry Sundae’ and ‘Lemon Meringue’ — to the forefront, as well as Mangaves, which are hybrids between Agaves and Manfredas.

Possessing an interest in plants that dates as far back as he can remember — as a child, he would ask his neighbors for plants “and they always said yes” — Hansen says he will look at a plant with a critical eye. “There are a lot of traits I like about it, but there’s something that could be improved on it,” he says. “I’m constantly thinking about how to make plants better, whether it’s in the garden or from a nursery, propagation, finishing standpoint.”

EXPANDING THE PALETTE: Hansen studied floriculture greenhouse production and environmental horticulture at the University of Minnesota. He then took a job at Shady Oaks Nursery in Waseca, Minn., where, in 1993, he began breeding hostas. Through this work, he began working closely with Plant Delights Nursery owner Tony Avent.

Hansen was running the tissue culture lab at Shady Oaks when Avent asked if Hansen could tissue-culture agaves for him. Hansen declined the request at first because at the time, Shady Oaks focused mainly on hostas, but he ultimately accepted. Then, Avent sent Hansen a new plant — a hybrid between an Agave and a Manfreda. Hansen and Avent’s mutual friend Carl Schoenfeld, of Yucca Do Nursery, had collected Manfreda variegata. Avent and Schoenfeld decided this new crop must have been a natural cross with Agave celsii.

WORKING WITH WALTERS GARDENS: Hansen hybridized Mangaves in Minnesota, but the work took off after he began working at Walters Gardens, where he says he has the facilities and the encouragement to thrive. “[Agaves] have a slow growth rate,” he says. “By crossing them with basically the deciduous relative that flowers every year, you can really accelerate that growth rate, to where some of these, depending on the cross, will flower [in] two, three years from seed. That’s faster finish times and a faster growth rate. It’s really interesting from a nursery perspective, because all of a sudden you get the price point down.”

Hansen’s Mangave introductions include ‘Kaleidoscope,’ which has lance-shaped leaves and shows off green, red, yellow and orange; and ‘Catch a Wave,’ a blue-green variety with upward-curled margins and an upright habit.

Out of Hansen’s commercially significant work with Walters Gardens, he says he has been working with hostas and baptisias the longest. “The baptisias take so long to evaluate that things that are just hitting the market were from work that I’d done many years ago,” he says. “But hopefully that has a lasting impact. Like peonies, if you plant a baptisia in a good spot in your yard, it will probably be there the entire time you own that property. With the drought tolerance and the low water input when it’s mature — the native factor — I think it has a lot of value.” — Patrick Williams

» Cut Flowers

Len Busch Roses, Plymouth, Minn.

WHY THEY’RE GREAT: The Busch family’s horticulture roots in Minnesota date back to the 1800s, when they emigrated from Germany and began growing vegetables. The second generation started growing flowers in 1920, and in 1965, the third generation founded what’s known today as Len Busch Roses. Now under fourth-generation leadership, the family-owned operation produces 7 million cut stems and potted flowers annually.

A major cut flower grower in the central United States, Len Busch Roses supplies retail florists and supermarkets within a 200-mile radius, providing a colorful variety of lilies, daisies, tulips, roses, snapdragons, sunflowers and more.

“What makes us great is that we’ve figured out how to grow in a northern climate,” CEO Patrick Busch says. “We’re able to produce premium quality flowers that don’t go through all the shipping, which allows us to harvest at a more mature stage, giving greater vase life and less mechanical damage. And we’re able to do it profitably and efficiently because of how we manage our processes.”

LEAN APPROACH: Through the generations, the Busch family has continued to innovate and improve. For example, all 15 acres of greenhouses are heated with environmentally friendly biomass boilers that burn tree-trimming waste from local communities. This is key to surviving Minnesota’s cold winters and competing in the northern market.

“If we didn’t mitigate the cost of heat for the greenhouses, we wouldn’t be profitable,” Busch says.

Len Busch Roses also employs lean manufacturing methodology to eliminate waste from its production, resulting in improved efficiency, productivity and profitability. The company has defined hundreds of processes within its operations, listing the sequence of steps and time cycles for each task.

By examining these processes step by step, they’ve been able to efficiently streamline production, effectively plan labor and continuously improve quality.

“For example, we used to have bunching lines,” Busch says. “We got rid of them because we found that by making the bunches and harvesting according to grade right in the bed, we could reduce mechanical damage on the flowers, which is something our customers are willing to pay for. And we could do it just as efficiently as we could by bulk processing on a processing line. That eliminated the cost of the (bunching) equipment, which doesn’t lend itself to small volumes, anyway.”

This lean approach helps Len Busch Roses stay competitive amidst labor shortages and increasing customer demands for quality — landing the company in our ranks of Greenhouse Greats. — Brooke Bilyj

» Grower-Retailer

Tina Bemis, Bemis Farm Nursery, Spencer, Mass.

WHY SHE’S GREAT: Being a savvy businessperson in a very competitive industry is what makes Tina Bemis, co-owner of Bemis Farms Nursery in Spencer, Mass., stand out in this industry. She and her husband, Ed, have been able to compete with big box stores by thinking outside of the figurative box.

“My philosophy has always been, ‘Nobody promised us business,’” says Bemis, who oversees a garden center, 15,000 square feet of undercover production space, 1 acre of outdoor production space, landscape design services and more. Bemis’ philosophy has helped her put aside any groans and gripes about the big guys and to rather focus on what they can do that the big-box stores can’t.

WILLING TO WORKSHOP: Big box stores don’t do workshops, Bemis says. This might not sound like an important consideration until you realize that workshops account for 15 percent of Bemis Farms’ revenue, which is what she says most garden centers make from perennial sales. The operation currently teaches 116 wreath-making workshops at its garden center and at garden clubs and schools. In the springtime, it hosts container gardening workshops: hanging baskets, porch pots, living wreaths — anything, she says, to put a plant in soil. “The workshops are what set us apart,” Bemis says. “Quality and customer service are a given now.”

THE IMPORTANCE OF THE DOORKEEPER: Bemis Farms has also helped its bottom line by adjusting how it approaches fundraisers and other events. “I’ve changed my tune over the years,” Bemis says. “I used to do whatever I could to get people into the store thinking they’d buy something, but it doesn’t pay the bills.”

The operation once hosted an Easter egg hunt that attracted 850 children, with parents in tow. Although it was a “feel-good” occasion, the large crowd didn’t exactly make the register sing. Since then, the operation has decided to charge each family $5 for its Easter egg hunts, and with that fee, customers can get $5 off any purchase at the register. “They’re not just coming out, petting the animals and leaving,” Bemis says. “We thought there would be less of a crowd, but there wasn’t.” — Neil Moran

» Marketing

Mariah Holland,

Metrolina Greenhouses, Huntersville, N.C.

WHY SHE’S GREAT: Mariah Holland, director of marketing at Metrolina Greenhouses, believes marketing is about creating a personal experience for the consumer. She says anyone can put a begonia in a pot and place a tag on it. Customers these days expect much more. Holland’s been getting the message across and telling Metrolina’s story by increasingly using video and staying active on several social media channels.

“It is important to bring the items to life for the consumer and together we get to tell the story,” Holland says. “Consumers have an innate emotional connection to our products that we can capitalize on if we provide them with the right information and tools to be successful.”

DEVELOPING A PASSION FOR PLANTS: Holland started out in retail in a garden center, which she said was the beginning of her love for plants. She studied business at Appalachian State University in Boone, N.C., and along the way, received her state plant certification. She then worked in a few different greenhouses in merchandising and sales before being hired in at Metrolina. The company was beginning to see a need to ramp up their marketing program. Her timing was impeccable.

MAKING CHANGES: “I was able to develop what I thought would be a solid plan,” Holland says. She worked closely with retailers on program product development, not only locally, but nationally. She also worked with pot suppliers to improve product packaging, and with R&D to look at current plant offerings — some of which she classified as everyday, “need-to have” items, and others that she saw as potential game-changers.

“I’d say where I made my first mark was in retail programs,” says Holland, “developing new packaging and then setting up accounts — having a person for each account.” Then came consumer research.

“Our consumer research is really important,” Holland says. “It’s one of our key pillars because our industry is predominantly run by men, and the consumer is mostly women, so it is really good to have the data to support some of the decision-making.”

FROM THE GROUND UP: Holland credits her “drive, dedication and passion” to her success at Metrolina, where she continues to set the pace and direction of the marketing program.

“Metrolina has allowed me to build the marketing department from the ground up,” Holland says. “Five years ago, it was a team of one, and today we have an amazing team dedicated to each customer, consumer research and creative development.” — Neil Moran

» Orchids

Matsui Nursery, Salinas, Calif.

WHY THEY’RE GREAT: Growing a rainbow of colorful orchids that fill 2.8 million square feet of greenhouses, Matsui Nursery claims the industry’s largest variety of orchid species.

“We are unique in that most of our competitors of similar scale grow only Phalaenopsis. We grow a significantly wider variety of orchids,” says President and CEO Teresa Matsui, whose father Andy founded Matsui Nursery in 1967 after moving his family from Japan to California.

INDUSTRY PIONEERS: Since 1998, the Salinas-based nursery has focused exclusively on orchids. That year, Andy Matsui launched the country’s first grocery retail program for orchids, becoming an industry pioneer.

Customers rave about Matsui Miltonias (also called Miltoniopsis) because they can’t find them anywhere else. Matsui Nursery was the first grower to offer Miltonias for retail sale, and to this day, “no one else grows Miltoniopsis on any meaningful commercial scale,” Teresa says.

Matsui Nursery sells its orchids wholesale to specialty florists and retailers. Though its greatest availability is on the West Coast, it’s open to expanding wherever demand leads. “We will serve any market in North America that makes sense, in terms of scale and transportation logistics,” Teresa says.

VALUE-ADDED PRODUCTS: Without losing its focus on orchids, Matsui Nursery recently expanded its product offerings to give retail customers a value-added solution.

“Everyone has concerns about the cost of labor, so we are looking to create products that leverage the volume of plants we have and transfer some of the labor costs from our customers to us,” she says. “Instead of just selling the plant, we also sell upgraded arrangements. A customer could just buy the plants from us, buy the foliage from somebody else, and buy the pottery from yet another vendor, and put it all together — and some of our customers do that. But we are trying to offer our customers a labor-saving solution, and that provides opportunities for us.” — Brooke Bilyj

» Perennials

Cavano’s Perennials, Kingsville, Md.

WHY THEY’RE GREAT: In addition to spreading a love of plants by growing more than 700 species — 99 percent of which are perennials — Cavano’s Perennials is helping young people advance their college experiences and jump-start their careers. Since 2015, the Kingsville, Md., grower began sponsoring one college student to attend the Perennial Plant Association’s week-long annual symposium each year, paying for flights, hotels and other expenses. In 2017, PPA presented Cavano’s with the Grower Award.

“It’s catching on,” says Ferenc Kiss, owner and president. “I was just in Denver, and I was approached by [a woman from] another company who has been involved with the PPA for a long time. She came up to me and said, ‘In 2018, we’re going to sponsor a student as well.’ That’s just fantastic, maybe we are setting up a trend there. We really need to show the young people out there that you can make this a career, and there are good people out there that will teach you and be your mentor.”

THE HISTORY OF CAVANO’S: George and Marlene Cavano began their cut flower operation in 1972, and Marlene’s son, Tom Hensler, took over in the mid-’90s. “That’s when they started to sell less of the cut flowers and decided [to move] more into perennials, because for residential plantings and commercial jobsites, that’s what people were asking for,” Kiss says.

Originally from Switzerland, Kiss traveled throughout Europe and worked various jobs. He moved to the United States in 1995 and three years later, started working for Cavano’s as nursery manager. He was later promoted to general manager, and in 2015, he and now-Vice President Taylor Pilker bought the company from Hensler.

FRIENDLY COMPETITORS: In addition to the PPA, Cavano’s is a member of the American Hemerocallis Society, Horticultural Society of Maryland, Landscape Contractors Association, Maryland Farm Bureau, Maryland Greenhouse Growers Association, Maryland Nursery and Landscape Association and Pennsylvania Landscape and Nursery Association.

Kiss says an eagerness to learn more about plants prevents many growers from keeping a trove of secrets. “Nursery people are a unique group,” he says. “We may be friendly competitors, but we still share information because there’s so much to learn. It’s just like this big family of people. I want to see people succeed and help them out as much as I can, and they help me out as well.”

THE JOY OF GROWING: Kiss’ father was a mechanic and his mother was a housewife. Neither of them worked in horticulture, so his interest in the field sparked on its own. “I kind of woke up one morning, and I felt like this is what I want to do,” he says.

Just as Kiss doesn’t quite understand other people’s love of other things — for instance, painting — he feels people might not understand his love of plants, and his love of perennials specifically, when he tries to describe it.

For now, he explains it this way: “They are resilient, they are sustainable, they are tough, they come from all over the world, there are so many beautiful American native species out there — and some selections and varieties. I think there is just something incredible about the tenacity, the way they grow, the toughness. They can grow in Northern Maine, they can grow in Northern Florida, they can grow in Central Oklahoma.”

A love for perennials, he says, is in his DNA. — Patrick Williams

» Plant Trialing

Kathleen Baughman, Iwasaki Brothers Greenhouse, Hillsboro, Ore.

WHY SHE’S GREAT: At Iwasaki Brothers Greenhouse, Kathleen Baughman helps lead different trialing efforts. Within the past few years, the Hillsboro, Ore.-based wholesale operation has conducted its own trials to determine if switching to LED lights from HPS lights is right for its business.

A LIGHTING FOCUS: Baughman started her career as a landscape architect after studying at Washington State University. During the latest housing crisis, she switched careers and moved to a rose nursery. She worked there for a few years before being hired as the IPM Manager at Iwasaki Bros., where she now serves as operations manager.

The operation started its first trialing with LED lighting three years ago after previously using HPS light that Baughman says weren’t offering the level of supplemental lighting Iwasaki Bros. needed.

“We bought our first lights three years ago before anyone was really using them,” she says. “It was a lot of self-teaching, a lot of trial and error. The results on those lights were interesting enough that we felt something was there.”

After the initial fixtures, Baughman also took an online course from Michigan State University, read industry research and talked with experts at trade shows to better understand how the LED lights worked. Currently, Iwasaki’s trials are split up into four quadrants that will grow the same plants under different light spectrums (and from different companies) to determine what spectrum works best for the business. Each plant will receive the same treatment in the germination chamber before it’s sent to a specific area in the greenhouse. Two quadrants are fitted with lights from Philips Lighting, one quadrant with lights on a different spectrum from Fluence Bioengeering and another retrofitted with HPS lights to offer some added context.

“We are actually starting another series of trials now,” she says.

For growers who want to carry out their own trials, Baughman has a simple piece of advice.

“It’s mostly just making sure you’re taking the time to go back and evaluate everything in production, which is probably the hardest thing to do because you want to do it during your real in-season schedule, but that’s also your busiest time of the year,” she says. — Chris Manning

» Research

University of Arizona’s Controlled Environment Agriculture Center

WHY THEY’RE GREAT: Established in 1998, The University of Arizona’s Controlled Environment Agriculture Center (CEAC) blends multi-disciplinary research programs with hands-on educational opportunities and outreach to explore the future of greenhouse production. The CEAC facilities range from high-tech automation to low-tech greenhouses, addressing a range of challenges and opportunities faced by growers with varying resources in various climates.

As acting director of the CEAC, Dr. Murat Kacira (who is a professor in the Department of Agricultural and Biosystems Engineering) sees exciting opportunities for growers to leverage the latest research to their advantage.

We spoke with him about his research on computer vision-guided crop monitoring and diagnostic systems, and how it will improve the efficiency of greenhouse production.

Greenhouse Management: What is the goal of your research on computer vision systems?

Dr. Murat Kacira: The ultimate goal here is to develop monitoring systems to help growers plan and manage their production with more precision, and optimize their resource use. We’re developing sensors and technologies that actually allow the plants to tell us about their needs for water, light, CO2 and nutrition so they can, in a sense, control their own environment.

Growers already have access to technologies with sensors that monitor or control root zones or aerial environments inside or outside of the greenhouse. If we can bring in physiological crop-specific information and integrate that with the other data that’s being collected from the root zone or aerial environment — and ultimately include all this information in a decision support system or a climate control application using artificial intelligence — that would empower the grower to enhance their management practices. It would increase control of the overall plant growth environment, which could improve resource use efficiency.

GM: How will this research impact greenhouse growers?

MK: This technology will provide growers with more meaningful data that will enable them to make improved decisions about managing their production systems and resources optimally.

As we know, one of the main burdens in CEA applications, in addition to energy use, is the labor use. For us to be competitive in the market, we will need more intelligence, more automation and more advanced robotic systems.

This doesn’t mean that these systems are going to replace the grower, but they’re going to empower the grower by working in collaborative ways that enable growers to manage labor and energy in a more effective way. We will still need the green thumb and hands of the grower helping out these automation systems to maintain the quality.

GM: What advice do you have for greenhouse growers, based on your research?

MK: Investing in appropriate technologies and digital systems will make it possible for growers to grow crops using a fraction of the resources used in field agriculture. This will enable growers to grow high quality-yielding nutritious food with resource-savings — and CEA technology should not only focus on the yield, but it should also consider how many resources we are inputting.

We need resource-saving systems to make us more efficient as we are challenged with the global demand for increased food yield and quality under the resource constraints and limitations we have. So, in that sense, CEA is really well positioned. I see great opportunities, especially with enhancing the integration of big data into CEA systems. — Interviewed by Brooke Bilyj

» Specialty Crops

Rocket Farms, Half Moon Bay, Calif.

WHY THEY’RE GREAT: In addition to growing poinsettias, roses, campanula and other common greenhouse-grown plants, Rocket Farms in Half Moon Bay, Calif., offers an array of specialty crops such as Venus flytraps, Aloe vera and edible herbs. The operation’s product lines, Plants for Wellness and Plants for Living, are designed to engage customers in a unique way, says vice president of marketing Jason Kamimoto.

Growing under 8 million square feet of covered greenhouse production space, Rocket Farms has eight to 10 core crops and a broad range of products in development, Kamimoto says. The grower sells completely wholesale, shipping finished packaged products. Meanwhile, its website and social media accounts — Pinterest, for instance — convey craft ideas, recipes, gardening tips and other information that is useful to both horticulturists and end consumers.

INTERACTIVE EDUCATION: Venus flytraps are often used as educational tools in classrooms and as plants that tend to appeal to families and children. “We get positive consumer responses from mothers and teachers on behalf of their children and students,” Kamimoto says. “The interactive appeal of this particular plant is a great opportunity to talk about plants, life cycles, care and information.”

A CHANGING DEMOGRAPHIC: Compared to older generations, younger customers generally prefer indoor potted floral and edible crops than more traditional bedding plants, Kamimoto says. “Younger consumers like a story behind the grower and the plant and appreciate high-quality, unique products,” he says.

One such high-quality product that end consumers enjoy is Aloe vera, which is used for topical applications to promote soothing and healing ailments such as sunburn and rashes, and can also be consumed as a healthy juice.

“Ultimately, we believe that edibles and indoor potted plants have a parallel message of healthy and happy living,” Kamimoto says. — Patrick Williams

» Up-and-Comer

Megan Haresnape, Kansas State University

WHY SHE’S GREAT: Kansas State University junior Megan Haresnape should give everyone in the green industry a reason to be optimistic. The ambitious horticulture major applied for and received three scholarships to study horticulture production at KSU — from the American Floral Endowment, Perennial Plant Association and Joseph Shinoda Memorial Scholarship Foundation. She has also learned several production responsibilities through her work in the on-campus greenhouses, and marketing and logistics skills through an internship. Looking ahead, she is thinking about opening her own greenhouse someday.

FLORAL INSPIRATION: Haresnape chose horticulture as a field of study after her mother allowed her to work alongside her in the garden when she was growing up. Her mother let her make some of the plant selections for the pots they were filling. It was something she truly enjoyed. When it came time to make a career choice, she thought about what she liked to do best.

“My dad always told me to find something you love in life as your job or otherwise you’ll be miserable,” Haresnape says. “So, I asked myself, where do I find a lot of joy, and I thought of being in the garden, working outside... so I started doing some research and ended up picking my major that way.”

HANDS-ON HORTICULTURE: In addition to book-learning, she has garnered a lot of hands-on training at KSU, working in the greenhouses on campus growing poinsettias, perennials and cut flowers. Haresnape, her boss and the two students with whom she works, stay busy. Their responsibilities are several, including, “watering, pest scouting, pesticide application, working with professors in preparation for their lab, working with graduate students and ensuring they have what they need for their research and helping maintain the greenhouses.”

Haresnape completed an internship at a food cooperative where she worked closely with producers and retailers in vegetable production. She took on management responsibilities, overseeing a harvesting crew of about six people. “I had a wide variety of duties — for example, harvesting, processing, going to farmers’ market, traveling and setting up produce stands, making wholesale deliveries to retail centers,” she says. “I did most of these things every week.”

UNBOUND OPTIMISM: Haresnape says there are more than 100 students in the horticulture program at KSU. She understands some people shy away from this field due to having to perform manual labor. However, she and her fellow students don’t appear to be afraid of getting their hands dirty. She says they’re optimistic about their future prospects in this industry. “Every time there is something new happening, we get all excited,” she says. “I don’t know if it’s because we’re plant nerds or what. Everyone I ever talk to is excited about what they’re doing.” — Neil Moran

» Website

Heart of Florida Greenhouses, Zolfo Springs, Fla.

WHY THEY’RE GREAT: Zolfo Springs, Fla.-based Heart of Florida Greenhouses sells interior foliage to independent garden centers, florists and other businesses in their area. Before it launched its website — heartplants.com — a year ago, orders were done by phone, fax and email and didn’t always allow for prompt, direct communication with customers. Now, utilizing a website built using Wix, a website building company that has pricing plans specifically for small businesses, sales manager Austin Bryant says the business has evolved to better serve its customers.

“Especially for a smaller company who can’t step out and hire someone to just build the website, someone has to wear a lot of different hats,” he says.

BUSINESS VALUE: Heart of Florida’s site has a few distinct features. For starters, a plant gallery with images of all of their available plants is located on the front page and updated regularly. Interested customers can also find a link to the “Plant of the Week” in the gallery if they are looking for something performing especially well. Secondly, the site has a sales portal that customers can log into and find their orders, price lists and any other information about plants they are interested in ordering. Order forms, credit applications and current availability are also available to customers with a few clicks.

Bryant says the business’ old site was built through Adobe products, but he didn’t have enough time to learn the ins and outs of the product. As a result, the site never became what he hoped it would.

“For me, as a small business, that goes way beyond what I’m willing to put a lot of time into to learn,” Bryant says. “I’ve got four kids, a business and not enough time.”

In using Wix, which allows users to drag and drop features and design choices when building the site, he picked a product that didn’t require learning how to code or any extra training. The end result is a website that both pushes Heart of Florida Greenhouses with a digital presence and better serves its customers.

“In the end, it’s all convenience,” he says. “It saves us time and it saves them the aggravation of waiting on us to get information back to them.” — Chris Manning

Explore the January 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners