With a name that is synonymous with “automation” in the horticulture industry, it pays to take note of the technology that Metrolina Greenhouses uses for environmental control.

The Huntersville, N.C.-based operation’s systems engineer Jeff Woolsey places his faith in Argus Controls. Among the grower’s uses for Argus Controls are heating, heat storage, fertilizer dosing, shade, blackout, fog control, germination and tray sterilization, he says.

Metrolina Greenhouses had chosen Argus Controls before Woolsey began working there, but he says the grower’s decision to use Argus Controls was based on the environmental control company’s competitive pricing and ability to fulfill various needs.

When Woolsey began working at Metrolina Greenhouses, he visited Argus Controls in Canada. “In the high-tech end of the world, things change — nothing lasts forever in high-tech,” he says. “One of my main missions was to see, ‘What’s our path forward?’ I didn’t want to spend money on something that was going to become obsolete. And Argus has been very good about backward compatibility.”

Early in his time at Metrolina Greenhouses, Woolsey tied the growers’ then-standalone boilers into a large, multi-range heating system. The biomass boiler system uses weather forecasting and is particularly sophisticated, he says.

Metrolina Greenhouses’ need for such a high-tech control system stems from both its penchant for automation and its massive size, Woolsey says. The heating system alone is 160 acres. “I know that they’re automation-driven and technology-driven, [and that] has been the case for all of those years — that’s definitely part of the formula,” he says. “But I think also, once you start getting up to a certain scale, you really need some centralized control, to maintain quality control and keep control, to know what’s going on.”

While most processes in engineering are done through feedback, Argus Controls uses an approach called feed-forward, Woolsey says. If growers rely on feedback technology, they fall behind, but if they rely on feed-forward technology, the control system can make decisions based on immediate factors, such as the sun rising, setting or going behind a cloud, or the temperature changing.

“If anyone asks me, ‘What’s the best thing about a computer for a greenhouse?’ my answer is simple: ‘Integration,’” Woolsey says. “You need a weather station, you need to know what the outdoor temperature is, you need to know what the light level is, the wind, which direction it is coming from.”

Aside from its products, Argus Controls is also known for its customer service, Woolsey says. “I really love their engineering, their quality control, the way they approach things,” he says. “Their system has been very, very reliable for us.”

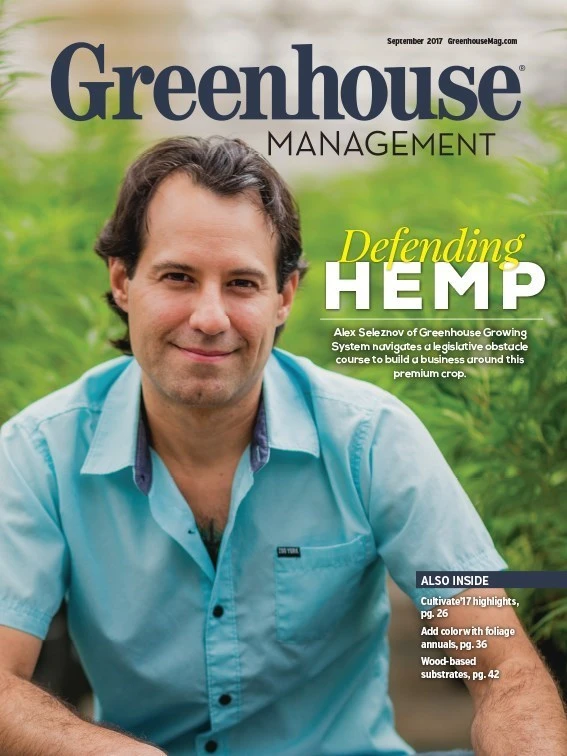

Explore the September 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners