At Bluestone Perennials, located in rural Madison, Ohio, the last year-plus has been a blur.

Like several green industry businesses, the second-generation nursery has been slammed for the past year with more and more consumers buying plants during their extended stay at home due to COVID-19.

“It was just constantly crazy,” says CEO Bill Boonstra. “We had a really hard time keeping up for a while there. But we made it through.” Half-joking, Boonstra says the entire workforce could have just been responding to email orders and that would have kept them busy for entire shifts.

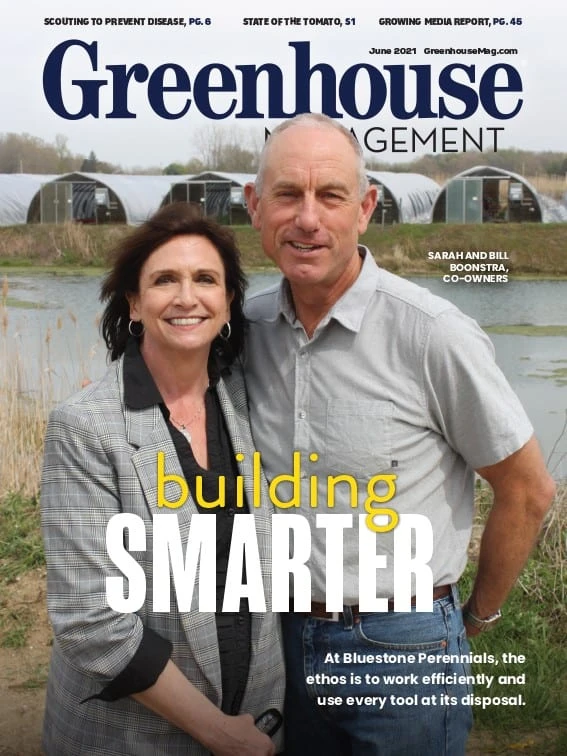

According to Boonstra – who took over the business from his father, Richard, and now runs it with his wife Sarah – the pandemic pressed on an already growing demand for the business. The company sells most of its products via a catalog, online orders and some in-person orders for local customers. In a normal year, this requires precise inventory intake, organized facilities and a flow throughout the business. During the pandemic — when in-person orders were at a halt until the limit slowly increased — this became even more important.

“We always have needed to work smart,” Boonstra says, “but it was really important in the last year or so. We were slammed all the time, hit capacity on orders and were getting called what felt like all day for orders. We’ve never needed to be on top of it like we were the last year or so.”

The importance of inventory

Dating back to the businesses’ founding in 1972 — back when the business consisted of just two rented glasshouses — inventory was done by hand at Bluestone. This isn’t an uncommon practice in any greenhouse or nursery, but it becomes increasingly difficult as a business adds space and ups its production capacity. Today, Bluestone’s inventory includes a wide variety of perennials, garden shrubs, ground cover and more.

According to Boonstra, the process involved a specific labeling for each greenhouse on the property. By going to a designated area, whomever is doing inventory or looking to fill an order can know exactly what greenhouse bay and row they are in at a given time. When the business was small, this was doable and not overwhelmingly time consuming.

However, as time went on and orders increased, Bluestone expanded well beyond its original capacity. This past winter alone, Boonstra says the business added several new structures to its facility to maintain demand now and in the future. (If another expansion comes, Bluestone does have land stretching well beyond its current structure lineup. According to Boonstra, however, there are no current plants to expand further.)

At times, demand has become so rampant that they had to stop taking orders for a day or two to catch up and get preexisting orders packed out in time. This past spring, Bluestone hit peak order numbers of around 1,800 per day. Two years ago, its peak was closer to 1,000 per day.

With the new structures coupled with increased demand, Boonstra says the manpower needed to do proper inventory by hand became too unwieldy to do efficiently. (The old marking system is still in place, however, as a backup.) The choice then became to either move workers from other departments to inventory or to try something new.

The company went with the latter option, since Boonstra believed moving workers around would only create more problems in Bluestone’s workflow. So, without a trial period, Bluestone began using inventory tracking software from Arbré Technologies, a Wisconsin-based start-up that produces RFID tracking and sensing products for various green industries.

According to Boonstra, incorporating the technology has been “fairly straightforward” at Bluestone. Each plant being tracked is stuck with a sensor tag that will then collect data from the plant and feed it back into the Arbré software for a Bluestone employee to view in an app. The sensor conveys fairly simple data such as where the plant is located on site and when it was planted. As much as a grower wants, more data can be tracked and sorted in order for the leadership team to make the best decisions possible.

“We are trying to ship faster and be smarter about it,” Boonstra says. “This and tech like it push us in the right direction.”

Empowering workers

Before installing the sensor tags, Boonstra says five employees spent their time working inventory almost exclusively. Now, that work has been whittled down to basically one person, freeing up workers to do other tasks needed or, when business is particularly busy, chipping in on inventory.

“This is freeing up some of our best people,” he adds.

Overall, empowering workers — and giving workers opportunities to thrive in the roles that interest them — is another key part of what Bluestone does. Over time, Boonstra says that it has found success by not sticking to rigid hours for workers. Instead, when they hire a new employee, they are willing to be flexible within reason.

For example: say a student at a nearby high school is looking for a part-time job, but also plays football and thus has limited hours due to practice, games and other training. Instead of ruling out that student from working at Bluestone, that student will set a work schedule around their school and activities schedule and work as much as they can. If more hours are wanted in the offseason, that’s OK too because there’s always more work to be done.

“We realized a long time ago that we needed to go to the workers directly,” Boonstra says, noting that they don’t have the luxury of being picky, being that Bluestone is located in a more rural area with a smaller workforce to pick from. “So, we offer flexibility and they will come in at a time that works for both sides and they’ll do what we need them to do for that time they are there.”

Over time, Bluestone has also made an effort to keep employees around for the long haul. This applies to a few older hourly workers who have been with the business for 10 or 15 years.

But this also applies to people who started working at the business in high school, doing something as simple as pulling weeds, filling or pulling orders that need to be shipped . When they graduate, some stay on and pick up more hours. Others head off to college and maybe pick up shifts if they are attending school locally or are home for a break. Beyond that, some even come back after college and work full-time at the business.

“We want to be a place people come back to,” Boonstra says. There are a few cases, he says, where an employee has pursued another degree altogether and then came back to work at Bluestone and make plants their career.

“It can get crazy here,” he says, “but the hope is that if we treat people right, they’ll invest in us like we’ve invested in them.”

The importance of being efficient

Every year, the entire Boonstra family – Bill, Sarah, their kids and grandkids – go on vacations to unwind and recharge. Their travels take them everywhere for a long stretch of the summer and involves hobbies such as wind surfing and hiking.

In that part of the year, the idea is to savor the earned break. All year, the entire Bluestone crew is likely busy all week and, in the case of some, working into the night. (Boonstra, for instance, will often work well past when the sun goes down and almost always works seven days a week.)

The labor required is why Bluestone has so readily embraced automation in recent years. Aside from the plant sensors, Bluestone has automated irrigation to reduce the need for labor to spend time on it. In the shipping and packing department, everything is organized in a structured system — orders are filled by one group of workers, neatly and securely packed in boxes and then sent up a conveyer belt to the shipping area where labels are printed, and orders are processed to go out.

In that space, every item has a specific home and specific package so there is no confusion about what goes where. In addition, another benefit of the tracking sensors is that plants can be earmarked for a certain order and tracked to make sure it gets to the right box. The idea is also for the process to be universal and have plants shipped correctly so that when a customer gets their order, it’s what they are expecting.

“This can get crazy — it did all last year,” he says. “So us investing in a process says us a lot of time and stress.”

Over the last few years, Bluestone has also made more of an effort to be operate sustainably. The sensors themselves can likely last several years. Elsewhere, the company’s pots are all made from recyclable material as to not use plastic and contribute to waste concerns. As Bill puts it, they know there’s only one Earth to grow on, so it’s important to do what can be done to treat it kindly.

During the busy season, Bill is probably doing a little bit of everything, while Sarah is handling a large amount of called in and online orders. Ultimately, they know that operating Bluestone takes time and effort from everyone involved. That is not lost on them when time finally does come to take a break.

“This job isn’t always easy,” he says. “It requires a lot and it likely means long days and hard work. But it’ll probably be worth it in the end when we get done and can look back at it and know we’ve earned that time away.”

Explore the June 2021 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- These companies are utilizing plastic alternatives to reduce horticultural waste

- Terra Nova releases new echinacea variety, 'Fringe Festival'

- AmericanHort expands greenhouse training with new Section Grower Certification

- Sakata Seed America celebrates renovation of Cal Poly greenhouse complex

- American Horticultural Society names winners of 2025 AHS Book Awards

- Nufarm announces unified brand

- American Horticultural Society announces winners of 2025 Great American Gardeners Awards

- What growers can learn from amateur plant scientists