Do you have a dust problem? Preparing and handling growing mixes and their components can create a lot of dust. This can result in health and safety issues for greenhouse employees. Good housekeeping, adequate ventilation and protective equipment can reduce the hazards.

Growing mixes come in bags that are emptied into the container filling hopper. Baled mixes need to be shaved or fluffed to make them ready for container filling. Growing mix traveling on conveyors gets dropped into the hopper or container. In all cases, dust is created. I have been in headhouses where there was a thick layer on the floor and on all the equipment.

Health risks

Almost all mixes contain components that make dust. Peat moss is the most common. Vermiculite, perlite, bark chips and compost all have particles that can float around and get into the lungs, eyes or throat. Particle sizes smaller than 20 microns (less than half the thickness of a human hair) are the most hazardous to breathe. These can cause respiratory problems including asthma and allergies. Other health problems from the dust include eye and skin irritation.

Mold spores from wood chips, sawdust, bark and composted leaves can also cause health problems, both mold allergy and mold toxicity, depending on the vulnerability of an employee’s immune system. Typical symptoms include coughing, wheezing and itchy eyes. More serious problems are headaches, exhaustion and sinusitis.

Fire risks

Peat has a low flammability rating, as it is usually moist. Ignition temperature is about 500 °F. If the dust is very dry, it can form a flammable dust-air mixture that can catch fire or explode if a flame or spark source is present. Common ignition sources include a fossil fuel furnace or boiler, a lit cigarette butt or a spark from an electrical switch. A rule to follow – if you can write your name in the dust, then it is time to clean.

Guidelines and regulations

Occupational Health and Safety Administration (OSHA): Material Safety Data Sheets (MSDS) cover most safety hazards for the different components of the mixes including peat, vermiculite, perlite, coir, wood chips, bark and compost. MSDS sheets are available from media manufacturers and suppliers.

National Fire Protection Association (NFPA): These standards relate to the prevention of fire and explosions from dust. Some such as NFPA 652 are specific to food and agricultural operations.

Communities may also reference some of these in their local regulations.

Control of dust

Housekeeping is important. End-of-shift cleaning of floors, equipment and horizontal surfaces should be done. Vacuums that meet Class II – Division 2 requirements should be used to avoid sparks. Sweeping and blowing dust should be avoided.

Use a light spray of water when shaving or fluffing the mix and while it is being conveyed. This will help to capture the dust.

Removal of the dust through ventilation is also necessary. An exhaust fan in one wall with a motorized shutter in the opposite wall works well to draw the dust away from employees.

Recommendations are to size the fan system to provide a minimum of five-volume air changes per hour for the room or area where the dust is generated. Doors, windows and vents in the area near the fan should be closed to avoid short circuiting of the air. If other operations or activities are in the same area, a temporary or permanent wall should be installed to separate the areas.

Explosion-proof, safety electric switches and motors should be used in the media preparation area and on the equipment.

No smoking signs should be posted throughout the area. N95 particulate filters should be available to employees.

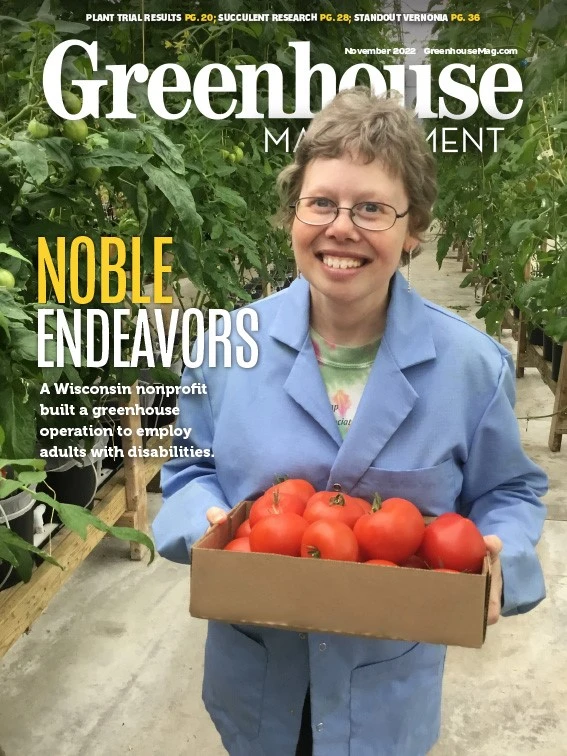

Explore the November 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners