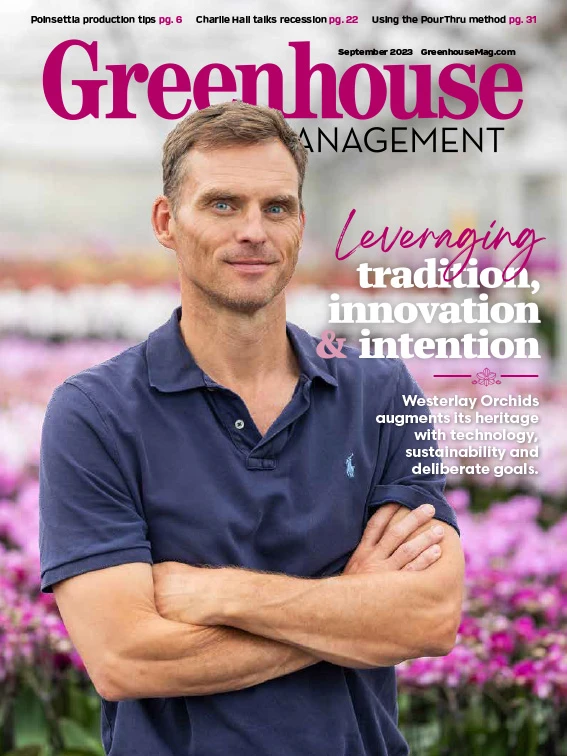

In 1983, when Stephen and Leslie Barlow bought the horticulture business that became Barlow Flower Farm, the property consisted of an old farmhouse and two retail greenhouses. 40 years later, the operation fills 28 greenhouses and a 10,000-square-foot retail structure as the second generation continues growing the family business.

After growing up around the business, their son Stephen took over as general manager. Their other son, Tom, spent time working in retail and culinary fields before returning to the greenhouse about eight years ago to help launch Barlow’s second location — a production facility in Wall Township, a few miles away from the original retail location in Sea Girt, New Jersey.

Now as head grower, Tom Barlow oversees growing at both locations as the brothers carry on their father’s legacy for producing quality plants. “I guess I got my dad’s green thumb,” he says. “I always enjoyed growing and it’s always been a passion of mine.”

Introducing new varieties

Today, Barlow’s spans 3 acres of covered production space, consisting of 28 4,500-square-foot Bartlett greenhouses, plus another 2 acres of outdoor production. Roughly 85% of Barlow’s production is grown for retail sale at the Sea Girt location, while the other 15% is sold wholesale to other garden centers.

Barlow’s crop mix consists of about 70% annuals and 30% perennials. Every year, the operation produces about 300,000 cuttings, 150,000 four-and-a-half-inch pots, 15,000 hanging baskets, and 30,000 mums.

In addition to tried-and-true lines, Barlow constantly trials new varieties, as well.

“I really enjoy getting into new petunia varieties like the Saguna series,” Barlow says. “It’s exciting to see the new genetics coming out.”

The retail location allows Barlow to experiment with new varieties and get direct customer feedback. “We’re fortunate because we can test the market ourselves, and we don’t have to spec grow,” Barlow says. “We’re able to introduce it to customers firsthand.”

Automating efficiencies

A team of about 10 people handle day-to-day production tasks like planting, flat filling, and spacing, while Barlow oversees growing. “I’m really hands-on when it comes to growing,” he says, “and I’m also a perfectionist about it.”

Barlow relies on technology to augment labor and automate manual tasks. In March, for example, the company purchased a new TTA sticking robot, and last year, the company invested in automated double-rail watering booms for several greenhouses. As much as Barlow loves hand-watering, calling it both “a joy and a meditation,” he doesn’t have time to manually water every house as the operation grows.

“We’re starting to see the benefits of using booms and being able to just program them and walk away,” he says. “I can put crops anywhere in a greenhouse and they’ll get watered exactly how I want. The cost savings has been amazing.”

Barlow also looks for opportunities to cut costs on growing systems. For example, they purchased old flood tables from another greenhouse and fixed them up for their operation. They also built and installed their own heated flooring in several greenhouses instead of buying ready-made solutions. “It’s been working great,” Barlow says. “We tried it on three of our 4,500-square-foot greenhouses, and we’re just going to keep going.”

Whether investing in new systems or repurposing older equipment, Barlow’s continues to improve its operation. “We're able to focus more on plant quality using all this new technology,” he says. “The technology has really allowed me to let the machines do the work and let me focus on the people and the plants. The more time I can spend focusing on the people and the processes, the easier the plants are going to grow.”

Knowledge transfer

Although Tom Barlow didn’t attend horticulture school like his father or brother, his knowledge came naturally.

“Most of the knowledge is just from working with my dad throughout the years,” he says. “My dad was so passionate about growing that there wasn’t a day that went by where he wasn’t talking about it. That passive knowledge gets to you.”

This knowledge transfer happens constantly in the tightknit family. Barlow’s founders, Stephen and Leslie, still live in the original farmhouse (built in 1807) and stay involved in the business. Their daughter, Stephanie, has a connecting yard next door; their son, Stephen, has a connecting yard next to that, and Tom lives on the other side of Barlow’s parking lot. “We’ve been able to maintain this nice family structure,” he says, “so every day, we’re around each other, and that’s important.”

These closeknit connections extend to the rest of the team as Barlow’s grows beyond the founding family.

“When you treat your people like you’d want your family to be treated, the results are exceptional,” Tom says. “There’s a certain level of care that goes into cultivating an employee relationship, and that makes a night-and-day difference in the quality of plants we’re able to produce.”

Explore the September 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- This month's Greenhouse Management magazine is about native plants and sustainability

- The HC Companies, Classic Home & Garden merge as Growscape

- Terra Nova releases new echinacea variety, 'Fringe Festival'

- Eason Horticultural Resources will now officially be known as EHR

- BioWorks receives EPA approval for new biological insecticide for thrips, aphids, whiteflies

- ScottsMiracle-Gro transfers cannabis subsidiary to focus on core lawn and garden business

- Should we start calling natives 'eco-beneficial plants'?

- Ellen Mackenbach-Lakeman appointed new CEO of Dümmen Orange