Metrolina Greenhouses, based in Huntersville, North Carolina, is one of the largest growing operations in the U.S., with 200 acres of growing space under cover. According to its website, Metrolina produces 11 million perennials, 6 million summer

Metrolina strives for precision at every step of the growing process, which can be challenging for a company with several big box store customers, more than 600 employees on staff and millions of plants being grown in the greenhouse. According to Nathan Wells, one of six head growers at Metrolina, the operation’s ethos is to grow each plant individually. To do this, he and the other head growers — as well as other greenhouse workers — go through the greenhouse daily and inspect each individual plant.

“When [customers] pick out the varieties we grow, they aren’t always the easiest varieties to grow,” says Wells. “But we try to get each plant looking as good as it possibly can. We find out if [the plant] is growing as it should be and if it needs to be sped up or slowed down. We always try to be on top of the crops.”

One area where Metrolina has found precision for every one of their plants is with the plant growth regulators (PGRs) they purchase from Fine Americas. According to Wells, Metrolina has worked with Fine Americas for the past several years and, over that time, they’ve been able to figure out exactly what works and what doesn’t for their operation.

“We’ve used them for several years, so we’ve got our [application] rates down,” Wells says. “We know what PGR works best with each crop and we seem to get consistency from the chemicals, so we know what to expect from them.”

For Metrolina, this is advantageous because it means the entire growing staff can operate with the confidence that the products will work as expected. With the scale Metrolina is growing at, there isn’t time to go back and fix mistakes — every part of the growing process must continue to move forward, or else entire orders could be disrupted. Wells also says Fine Americas has always been available when Metrolina has questions about the products it’s already using or potential new products the operation. And Fine Americas also visits Metrolina’s greenhouse to offer any on-site assistance that cannot be done by phone or email. Wells says this only helps his confidence in Fine Americas’ PGRs.

“In my experience, we’ve never had problems with them,” Wells says.

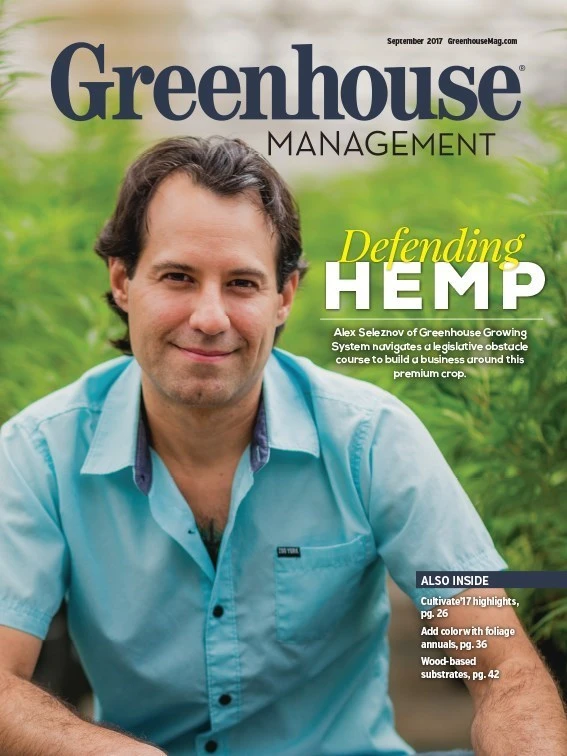

Explore the September 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners