For four days in January each year, IPM Essen opens its 14 halls to the global horticulture market. Inside, growers, retailers, breeders, brokers and other interested parties can learn about new technology, plant varieties, growing methods, trends, cut flower design and everything in between. More than 57,000 attendees from 45 countries visited IPM Essen and its 1,577 exhibitors from Jan. 24 to 27 in the city of Essen, Germany, this year. Sustainability was a theme throughout the trade show, from eco-friendly packaging to energy and resource-saving technology, especially in the field of automation. In addition to the usual floriculture focus, IPM also put a special emphasis on fruit and vegetable production this year. Exhibitors that had products that would be useful for produce were identified with a special logo. Here are some of the takeaways from IPM Essen in the areas of technology, trends, plants and more. Throughout the article, you’ll also find commentary from North American horticulture industry professionals about what they saw and why they attended. We couldn’t fit everyone’s insights into the article here, but you can visit greenhousemag.com to read the rest.

Technology

As could be expected, technological advancements were at the forefront at IPM Essen, with one of the biggest halls dedicated to technology. There were many lighting companies at the show, each with a slightly different take on the best way to distribute light to plants, whether it be in a supplemental or sole-source lighting set-up. LED technology has come a long way in recent years, and most of the lighting exhibitors had at least one LED option, whether it was intended to replace existing HPS fixtures or form a hybrid system. It was clear, however, that growers want to utilize the available lighting options to improve production, and many are considering LEDs.

On a consumer level, LEDs were also present in several consumer products. One example was the Sunlite, a growlight that looks like a tiny version of a lamp you might have in your home, used to boost the lighting for houseplants.

There were several examples of updated technology for multi-level growing, such as the moving gutter system named Multi Green Grow from Danish greenhouse manufacturer Viemose-Driboga.

One interesting innovation was a new 3-D plant sorting and packing system by Willburg Projecten. The Plant Vision System analyzes the plants coming through on the conveyor belt and sorts them into separate rows depending on the programmed parameters. According to Paul Rademaker of Willburg Projecten, the system doesn’t require special cameras, which makes it more accessible for smaller growers. Rademaker said that the sorting technology used in the Plant Vision System can be compared to technologies like the road sensing sensors that Tesla uses in its driverless systems.

CO2 injection can be beneficial for many crops, but growers can get too much of a good thing, according to Gertjan Bosman, product specialist at EMS. Oftentimes, a grower won’t know that their CO2 or other harmful gas levels are too high until measuring them with a system like EMS’ MACView greenhouse gas analyzer, displayed at IPM. Not enough growers are measuring these gases, Bosman says, and they could greatly benefit from understanding their levels and adjusting their production accordingly.

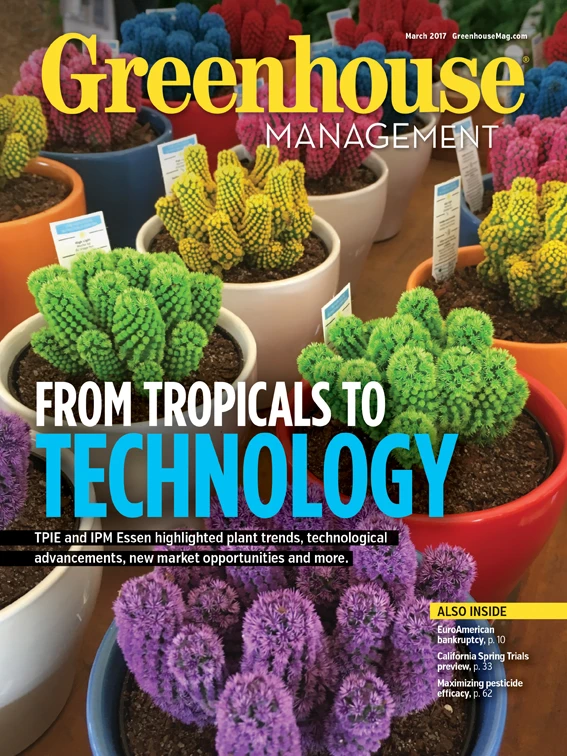

Color and design trends

In contrast to the more colorful displays seen a few years ago at European trade shows like spoga+gafa, neutral, natural colors and materials were at the forefront at IPM Essen this year. Wood was one of the most widely used materials, showing up in displays in the form of pallets, decorative twigs, trunk slices as pot stands, or as the material for the pot itself, although sometimes it was a plastic pot with a faux wood look.

Paper was also a popular material for both potted plants and displays. Several companies featured plastic-free pots and packaging, like Cox, a German herbs wholesaler with wild black pot sleeves that proclaimed they were zero percent plastic. Fellow German company Weber Verpackungen offered its own sassy paper pot sleeve, as well as a half plastic, half paper option and a mostly paper version. These companies and others broadcast an eco-friendly message, with some noting how much plastic would be saved by switching to paper.

Metallic colors like silver, bronze and copper remained prevalent for pots, often with color-coordinated plants.

Over in the Danish section, there were many fun, whimsical pots and containers, some with bright colors, which was a contrast to most of the rest of the halls.

Explore the March 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners