Because the beginning is the most important part of the work, as Plato purportedly wrote, Timbuk Farms’ young plants division continually adopts practices to grow and ship superior liners.

Because the beginning is the most important part of the work, as Plato purportedly wrote, Timbuk Farms’ young plants division continually adopts practices to grow and ship superior liners.

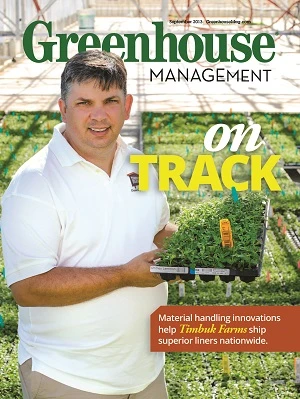

The Granville, Ohio-based grower has a notable history in liner production. In the ‘80s under the Schmidt family ownership, Timbuk was one of the largest rooting stations for Ball Seed, said current owner Jim Gibson. And in the ‘90s, Timbuk was one of the first to pioneer liner production from offshore sources. Gibson was a Ball Seed sales rep during that time, selling product to Timbuk. In 2007, Jim and his wife LaVonda purchased the company. Since taking over Timbuk Farms, the Gibsons have invested heavily in production efficiencies to grow and ship millions of plants.

Timbuk Farms is now a rooting station for Ball FloraPlant and for Dümmen. Between the two suppliers, Timbuk carries some 1,400 line items.

On the move

To help keep material handling and order pulling running smoothly, Jim designed the Gro-Rack system with the help of AgriNomix. The system was designed so liner trays are grown and moved on the same bench from propagation to shipping allowing for minimal touches.

Timbuk’s system, which was inspired by a similar system at Seacliff Greenhouse in Canada, fits 10 trays on a stackable bench. The benches can be stacked 10 high. Once the trays are ready, an electric cart pulls the benches to the greenhouse and two people set them down on the greenhouse floor. When the plants are ready to be moved, workers restack the benches and take them to the next destination, whether it’s a different production area or the shipping docks.

“It’s a simple system, but it’s made things so much better and more efficient in the greenhouse,” Jim said. “The trick is to think of production based on a bench instead of a couple of trays.”

|

Specifics Name: Timbuk Farms Location: Granville, Ohio Founded: In 1952 as a Christmas tree farm by Jack Schmidt Sr. In the early 1970s, Jack Schmidt Jr. built a greenhouse operation. Jim and LaVonda Gibson took over the business and purchased Timbuk Farms in 2007. Timbuk continues to operate a Christmas tree farm. Production space: 400,000 square feet under cover and 10 acres of outdoor production. Primary products: Young plants; finished bedding plants, fall mums and poinsettias. Sales/shipping area: Young plants are shipped nationwide. Finished plants are shipped throughout Ohio and the surrounding states. |

The benches provide a microclimate underneath the trays. And the system is more efficient than fixed or rolling benches, Jim said.

Material handling efficiency has increased by 20-30 percent, he said. Jim expects a three- to four-year payback.

“The benches were a big investment. We’ve used this system for two seasons and we keep finding ways to make it work even better for us,” he said.

Timbuk adding a trimming machine and a watering tunnel that works with the Gro-Rack system, also with the help of AgriNomix. Watch a video demonstration of the system at www.agrinomix.com/movies/grow_racks_2.html.

|

Fun Fact Timbuk Farms began in 1952 as a Christmas tree farm. At the time the dream of a Christmas tree farm became a reality for the original owners, the Schmidt family, Granville was quite remote from Columbus. A drive to the farm from the family home in Columbus was like a trip to Timbuktu. That is how the farm got its name, shortened and simplified to Timbuk Farms. The farm continues to be one of Central Ohio’s oldest and largest Christmas tree farms. |

Smart systems

Once the Gro-Rack system was in place, Timbuk looked for the next step to enhance the inventory and handling process. The grower implemented SBI Software’s production module.

“All trays are scanned in and out for accurate order fill,” Gibson said. “Our ultimate goal was to have 100 percent error-free scan and not have to hand count trays.”

The system can track where every tray and every Gro-Rack bench is in the greenhouse. The Timbuk crew performs all the functions of the SBI software on iPads.

The system can track where every tray and every Gro-Rack bench is in the greenhouse. The Timbuk crew performs all the functions of the SBI software on iPads.

Timbuk also relies heavily on the system to track labor. “We know the speed and accuracy of sticking for each crop,” he said.

Besides equipment and technology, Jim and LaVonda have invested in reliable and clever people to help run the operation.

“Our managers and employees have done so much for our company,” Jim said. “And we have a lot of customers that have supported us over the years. We couldn’t do this without our team or our customers.”

Full-service firm

Timbuk also grows finished plants – including bedding plants, vegetables, fall mums and poinsettias — and operates a retail division. Retail locations include a permanent store in Granville, and three satellite locations in Mt. Vernon, Newark and Lancaster, Ohio.

With divisions across the entire horticulture supply chain, Gibson was eager to be a part of the new HGTV Home Plant Collection. Timbuk Farms is an HGTV licensed grower of young and finished plants.

|

Certifiably Sustainable Timbuk Farms received an MPS certification in 2012, which verifies that the grower meets a number of sustainable production standards. MPS tracks all inputs including water, chemical and energy use. After capturing data on inputs for 13 months, MPS audits growers and gives them scores for each data set. Timbuk got involved with MPS because it was a good business tool and allows the company to use inputs more efficiently. “We’re able to make some good business decisions based on the data,” said Jim Gibson, Timbuk’s owner. Timbuk has been tracking data for almost two years. The grower had already implemented several sustainable business practices prior to the certification process, but with the MPS tracking, Gibson can see where the dollars are being spent, he said. “Before MPS, we were using best management practices throughout the greenhouses,” he said. “But with this takes it a step further because you continually track it and they hold you accountable.” Businesses are recertified each year. The MPS certification is important to many of Timbuk’s customers. “It’s an important aspect of our company and it’s good for business,” he said. Gibson is researching another certification from MPS called GAP or good agricultural practices. Gibson said this certification is geared toward crop protection agents and traceability. For more: www.my-mps.com |

“We felt this was a good program for our independent garden center customers,” he said. “What I really like about it, is it has 95 percent brand recognition. They’re already a well-known brand.”

He’s been able to expand into new markets with this program, and this year he plans on doubling production of the finished plants in the HGTV Home Plant Collection.

He was able to test the collection in the Granville store.

“In our store, the HGTV brand had a huge connection with our younger customers,” he said.

For more: www.timbuk.com

Photography by Joshua Bickel

Explore the September 2013 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- A nation of gardeners: A history of the British horticulture industry

- Last Word with Angela Labrum, Bailey Nurseries

- Iowa plant supplier Plantpeddler building retail complex

- This month's Greenhouse Management magazine is about native plants and sustainability

- The HC Companies, Classic Home & Garden merge as Growscape

- Terra Nova releases new echinacea variety, 'Fringe Festival'

- Eason Horticultural Resources will now officially be known as EHR

- BioWorks receives EPA approval for new biological insecticide for thrips, aphids, whiteflies