Ornamental plant production in greenhouses, like most businesses, is planned according to a unit sales forecast. The number of plants is easily planned, but that is where the challenge of working in a biological industry begins. Plants, simply put, are biochemical reactors that are subject to chemical reaction rates.

Ornamental plant production in greenhouses, like most businesses, is planned according to a unit sales forecast. The number of plants is easily planned, but that is where the challenge of working in a biological industry begins. Plants, simply put, are biochemical reactors that are subject to chemical reaction rates.

The popular rule of thumb for biological systems is that reaction rates double for every 10°C of temperature rise, up to a limit. So, temperature dictates plant mass, or quantity. However, quantity of ornamental plants does not guarantee profitable sales without sufficient quality. Quality is a short-lived aspect of plant production that is critical to profits, and the greenhouse climate is critical in determining crop quality.

Quantity and quality, alone or together, do not guarantee profit without timing. Hitting market windows is critical. We all know that the spring weekends are precious and that there are no New Year’s markets for the poinsettia.

Heating, cooling, ventilation and air distribution combine to result in a climate that is confined to a rather narrow range of conditions. This environment, hospitable for plants yet hostile to pathogens, is crucial for success. Greenhouse climate screens, or energy/shade curtains as they are frequently known, are frequently installed for insulation to reduce heating and cooling costs. However, recent research reinforces the benefit of curtains in creating a climate more favorable to plant production.

Temperature is linked to development

The rate of plant development is dictated by the mean daily temperature of the shoot tip. In 2001, research at Michigan State University demonstrated that campanula time to flower was reduced by about two weeks by increasing the temperature of the shoot tip from 16 to 24°C.

Recently it was reported that growing New Guinea impatiens underneath a greenhouse curtain raised the shoot tip temperature by 0.5 to 2.3°C as a result of increasing the long wave radiation to the plant, which was 70 to 125 percent greater than the case with no curtain in a glasshouse. The study was to quantify the effect of using greenhouse curtains on an economically important crop that’s known to be delayed by low temperatures (Figure 1).

More long-wave radiation on the crop is the result of the plant being surrounded by an environment with higher surface temperatures. Plant temperature, or a plant’s thermal equilibrium, is a result of a leaf energy balance. That is, the realized leaf temperature is an indication of the balance of energy coming into the leaf and energy leaving the leaf.

Energy coming into the leaf is direct, absorbed solar radiation and absorbed infrared radiation from the surroundings. For a plant on a greenhouse bench or floor, the underside of the glazing or a curtain, if present, makes up a large portion of the plant surroundings.

Energy leaving the leaf is from emitted infrared radiation, heat convection, heat conduction and heat loss that accompanies evaporation in the transpiration process. Emitted infrared radiation is largely dependent upon surrounding surface temperature differences. The lower the temperature of the overhead surface, the greater the emitted infrared radiation loss (Figure 2).

It is well documented that using greenhouse energy curtains conserves 25 to 40 percent of annual energy expenditure. By using the USDA’s Virtual Grower 3 software, we can estimate the impact on the shoot tip temperature increase of the plant. In this case, we use impatiens. Most growers use greenhouse dry bulb air temperature as a crop climate steering parameter. From an energy-saving perspective, if a grower dropped the air temperature during the first quarter of the year by the 2.3°C, it would reduce the annual heating requirements by 10 percent.

Or, viewed in a different manner, according to the development predictor function in the Virtual Grower software, the temperature difference has a three-day influence, or more than 10 percent of the production time. When considerable efforts are being made to turn growing space in the early spring, three days can be significant.

Hospitable (to plants) yet hostile (to pathogens)

Temperature regulates plant development but also regulates multiple and various pathogen activities. Greenhouse and environmental control equipment generally aims to provide near optimum temperatures for crop productivity. Optimum temperature for plant growth processes may often coincide with the optimum for pathogen activity.

The strategy for mitigating pathogenic activity is to satisfy the thermal needs of the plants while minimizing free water and wetting the crop as to not invite infection. Whereas the crop canopy will have a distribution of temperature, good air circulation will help leaf temperatures to be closer to the air temperature.

Further, the previously mentioned higher shoot tip and leaf temperature that results by high long-wave radiation gain will aid in keeping plant surfaces above the dew point temperature where water forms (Figures 3 and 4).

Infrared thermography

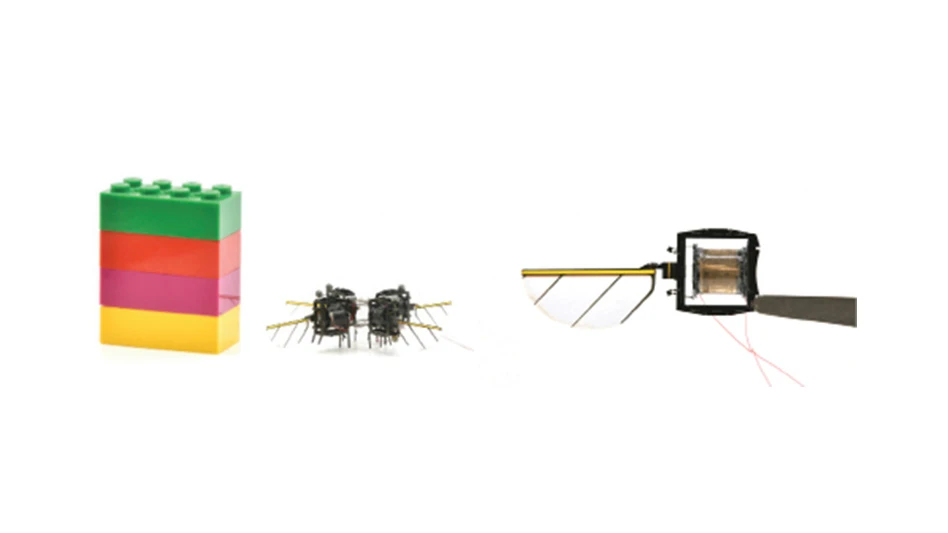

Long-wave radiation is a phenomenon that is more easily sensed on our skin than visualized in the greenhouse or even the greenhouse climate computer screen, where dry bulb temperature and relative humidity sensors gather most of our intelligence. However, the field of infrared thermography has developed tremendously in the past decade as a result of greater demands from applications in military, security, as well as industry and science needs.

Use of affordable, hand held thermal imaging cameras can serve two departments in the greenhouse operation. First, the energy manager and maintenance manager can review the effectiveness of the sealing of glazing and curtains systems. They can also find electromechanical issues that may be developing by seeking out hot spots in electrical panels or motors.

But, perhaps as an even bigger benefit, a grower can use thermal imaging to get an impression of environment and make a judgment on plant comfort, which will relate to health and productivity. Colder leaves will be growing more slowly and ultimately be wetted first, which may invite pathogenic activity. Temperature distributions can be monitored and give explanations as to why perhaps plants near perimeter sidewalls or vents may be growing more slowly.

This type of information can lead to decisions such as insulating sidewalls or increasing the amount and direction of airflow (horizontal or vertical) that is utilized for mixing and ultimately temperature uniformity.

Note the thermal images that were taken within a tall canopy crop. See that the heat pipe is the warmest zone and the glass the coldest. Note also the temperature distribution of the plant canopy (Photo 1). All leaf surfaces with a “view” of the cold glass (Photo 2) have a lower temperature as a result of greater long-wave radiation loss to the glazing.

Note the thermal images that were taken within a tall canopy crop. See that the heat pipe is the warmest zone and the glass the coldest. Note also the temperature distribution of the plant canopy (Photo 1). All leaf surfaces with a “view” of the cold glass (Photo 2) have a lower temperature as a result of greater long-wave radiation loss to the glazing.

Whatever method we use, analyzing and managing environmental factors including temperature are vital to successful greenhouse ornamental plant production. Choosing the right method or combination of methods can be critical to your business’ profitability.

Kurt Parbst is president of Ludvig Svensson Inc. He can be reached at (704) 357-0460 or kurt@svenssonamericas.com.

Do you know someone that has made a positive impact in the horticulture industry? Nominate them for a Horticultural Industries Leadership Award (HILA)!

| SUBMIT NOMINATION |

Explore the November 2012 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Meet the Next Gen: Gabriella Blair, Star Roses and Plants

- Leading Women of Horticulture: Katie Dubow, Garden Media Group, and Aubry Field, Lizzy Blossom

- Showing up at your horticulture business as your whole self

- Leading women of Greenhouse Management

- USDA fires experts on invasive pests, including Asian citrus psyllid, chilli thrips

- Farwest Show calls for 2025 New Varieties Showcase entries

- Leading Women of Horticulture: Arden Pontasch, North Creek Nurseries

- Leading Women of Horticulture: Emily Showalter, Willoway Nurseries