In a world where you can customize anything from cell phones to M&M candies to cars, greenhouses are no exception. When the Ohio Agricultural Research and Development Center (OARDC), located on Ohio State University’s (OSU) campus in Wooster, Ohio, suddenly needed a new greenhouse, they knew that a custom solution would be the best fit for their needs.

In a world where you can customize anything from cell phones to M&M candies to cars, greenhouses are no exception. When the Ohio Agricultural Research and Development Center (OARDC), located on Ohio State University’s (OSU) campus in Wooster, Ohio, suddenly needed a new greenhouse, they knew that a custom solution would be the best fit for their needs.

A whirlwind of change

On Thursday, September 16, 2010 at approximately 5:30 p.m., disaster struck. A strong storm culminated with a tornado that ravaged the campus, extensively damaging many buildings, including several greenhouses. Michelle Jones, faculty member in the OARDC Department of Horticulture and Crop Science recounts that most of the staff and students had already left for the day and when the warning sirens sounded, they had about 5 or 10 minutes to get to the basement before the tornado hit. Fortunately, there were no serious injuries reported. Unfortunately, the greenhouses didn’t fare quite as well (nor did Jones’ car — but that’s a story for another time).

“After the tornado the greenhouses were a mass of metal and glass,” Jones says. While the Gourley greenhouse was eventually able to be salvaged with repairs to the structure and glazing, the Williams greenhouses had to be completely demolished, leaving researchers and graduate students previously working in the facilities in the lurch. Temporary greenhouses were constructed in the months following the tornado for Gourley and Williams greenhouse users, and they planned to begin the search for a design-build team to create a replacement facility for the destroyed Williams structure. Jones, chair of the Department of Horticulture and Crop Science’s faculty-based greenhouse committee, has been intimately involved in the process.

“One of my biggest jobs [as chair of the greenhouse committee] in the last couple of years has been this new greenhouse that we’re building after the tornado,” she says. The greenhouse committee also worked with greenhouse manager Mike Davault to develop the policies and procedures for the greenhouses and help with the assignment of individual spaces within the structure. Davault currently manages the Gourley greenhouse complex as well as the temporary greenhouses, and will again manage the new Williams complex upon completion. He has also been involved in the project.

Unique needs, unique solutions

After conferring with a consultant at Iowa State University, the OARDC team realized that their needs were unique, as the OARDC conducts research on everything from soybeans to grafted tomatoes to dandelions to petunias. “[My main focus is] looking at increasing production efficiencies in greenhouse crops but also looking at maintaining quality in the post-production stage,” says Jones of her own research. “We have a lot of collaborative projects with growers in the state as well as other universities.” Within the OARDC there are also programs in the plant pathology and entomology departments, and the School of Environment and Natural Resources (SENR), that conduct greenhouse research. In addition, the OARDC houses researchers from the United States Department of Agriculture-Agricultural Research Service, who conduct research in collaboration with the OARDC staff.

That meant that the design-build team that they hired needed to be able to come up with a solution that satisfied the needs of all of the researchers and departments at the OARDC. Several teams were interviewed by the OARDC representatives, including Jones, and a decision was made: they would go with the design-build team headed by LL Klink & Sons, a greenhouse construction, maintenance, repair/renovation, design-build and supply company, and Consolidated Greenhouse Solutions (CGS), a greenhouse services company that is EDWOSB (Economically Disadvantaged Woman Owned Small Business) certified.

That meant that the design-build team that they hired needed to be able to come up with a solution that satisfied the needs of all of the researchers and departments at the OARDC. Several teams were interviewed by the OARDC representatives, including Jones, and a decision was made: they would go with the design-build team headed by LL Klink & Sons, a greenhouse construction, maintenance, repair/renovation, design-build and supply company, and Consolidated Greenhouse Solutions (CGS), a greenhouse services company that is EDWOSB (Economically Disadvantaged Woman Owned Small Business) certified.

.jpg) “Without going into any specifics about the different teams and what they brought to the table, our comfort level was very high with the Klink team because they had the expertise in greenhouses and the team members including CGS that brought in the knowledge of all of the specific trades,” says Jones. “Also, in past projects, the users were not nearly as involved in the process. We haven’t always known why they chose specific pieces of equipment and sometimes those weren’t the best choices for the researcher.” And a greenhouse that’s not usable for everyone isn’t going to be a worthwhile investment.

“Without going into any specifics about the different teams and what they brought to the table, our comfort level was very high with the Klink team because they had the expertise in greenhouses and the team members including CGS that brought in the knowledge of all of the specific trades,” says Jones. “Also, in past projects, the users were not nearly as involved in the process. We haven’t always known why they chose specific pieces of equipment and sometimes those weren’t the best choices for the researcher.” And a greenhouse that’s not usable for everyone isn’t going to be a worthwhile investment.

The team

Becky Yount and Sylvia Courtney, principals at CGS, are no strangers to the horticulture industry, and have built strong relationships with industry vendors over the years. Yount had worked for a greenhouse manufacturer for 24 years prior to CGS, and Courtney has a degree in horticulture and has worked in the industry since 1977. “Becky [Yount] is really good at the marketing, networking and project management, and I’m more effective at the upfront, technical parts,” says Courtney. “We try to divide our time between who’s more effective at doing what.” CGS had developed a solid working relationship with the LL Klink team through their collaborations on other projects in the past.

This was not the first time Yount and Courtney had worked with OSU. The CGS team has been working with Joan Leonard, program manager for arts and sciences plant growth facilities at OSU’s main campus in Columbus, on retrofit projects for two of the 1990s greenhouses there. And it’s not always as easy as replacing parts that are broken because sometimes the parts are no longer being manufactured, meeting code or are too costly for the funding available. These are challenges that CGS has learned to work around. This creative thinking has come in handy with the Williams complex.

“This is a design-build project, and we were given a set of criteria and some drawings,” says Courtney. “We evaluated what was on those drawings and the budget and determined what was and wasn’t going to work. During the review process we made recommendations for changes to bring the project closer to the budget and presented the changes to the owner.” For example, the cooling system, originally planned to be a high pressure fog system and exhaust fans with variable frequency drives (VFD), was changed to a modified fan and pad system that would still be functional for their research purposes, but not quite as expensive.

Keeping the conversation flowing

As the project progressed, the OARDC was kept in the loop, which isn’t always the case with design-build projects. “It was a continual consulting with the user group all the way through, even though they’re not at the construction table with the contractors,” says Yount. “As items came up that we thought would affect them, we could go back to them and give them their options. They would sometimes ask Sylvia [Courtney] for recommendations, and we would go back to the table with their decision.”

The importance of this open communication between the design-build team and the user group was evident when the topic of benches came up. As much of the research being conducted at OARDC focuses heavily on breeding, genetics and non-production-related projects, their needs are different than a typical production greenhouse, which is looking to maximize square footage with the greatest amount of bench space. “The original designs included bigger benches that were very close together. We could put a lot of plant material on them, but it’s not an effective research space for us,” says Jones. “When I have people in my greenhouse rooms, they have to be able to get on both sides of the bench and reach the middle to pollinate plants and collect tissue without knocking the plants over.”

|

Experience is the greatest teacher Almost never does a project reach completion without enduring some modification due to a change in circumstances, an unforeseen delay or roadblock. For example, in the case of the new Williams greenhouse complex, the builders had to wait a month for the ground to thaw- having to dig through 2 feet of frozen earth just wasn’t feasible. If you’re planning on building a new greenhouse or undertaking a large project in the near future, keep these four considerations in mind. Have a comprehensive list of your wants and needs for the project, but recognize that modifications may be necessary to stay within budget. Creative thinking on the part of the design-build team can often achieve the original goals, but perhaps it won’t be by using the latest technology or the exact product specified in the original plans. Hire experts in the field who are invested in the entire process, from design to build. As the OARDC design-build team discovered, some necessary adjustments didn’t become apparent until construction had started. But because the whole team was still involved in the process, those adjustments could be made. Keep the lines of communication open between team members. When many specialized parties are involved, if they aren’t careful, one hand may not know what the other is doing and may duplicate efforts or cause conflicts. Proper planning now prevents potential inconveniences or serious problems later. “I’ve worked on projects where we have pieces of equipment that require power, but [initially] there’s no power going to the pump, or heaters that nobody ran a gas line for,” says Courtney. From those experiences, she knows how crucial it is to extensively review and double check plans, as well as keep in close contact with those working on specialized areas of the project, like plumbing or electrical. |

In addition, the most advanced technology wasn’t always the most appropriate for this research facility, an important aspect for Yount and Courtney to consider. “Are you doing your client a disservice by putting all that new technology in there just because it’s new technology?” asks Courtney. “It’s not that you shouldn’t try some of the new things, but on a limited basis until you figure out how that best works with what you’re trying to accomplish with the project.”

It was also crucial to evaluate the existing facilities across the campus. “We didn’t want to reproduce those exactly as we want to have a flexible environment here that meets as many of our current and future research needs as possible,” says Jones.

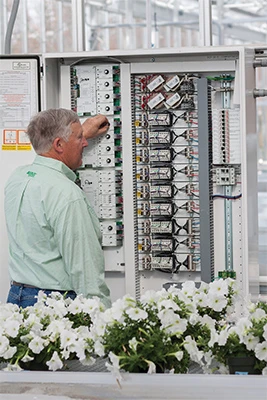

Once one of the rooms in Williams was completed, Davault had the chance to go through and evaluate its efficiency and utility for the OARDC’s purposes and suggest modifications. Davault will also have the unique opportunity to compare the older systems in Gourley with the new technology in Williams. “I’m looking forward to seeing what kind of environmental [conditions] I can maintain in Williams versus Gourley, particularly next summer,” he says. “It’ll be a fun comparison for me as a greenhouse manager to compare a newer and more sophisticated system with an older system.”

Once one of the rooms in Williams was completed, Davault had the chance to go through and evaluate its efficiency and utility for the OARDC’s purposes and suggest modifications. Davault will also have the unique opportunity to compare the older systems in Gourley with the new technology in Williams. “I’m looking forward to seeing what kind of environmental [conditions] I can maintain in Williams versus Gourley, particularly next summer,” he says. “It’ll be a fun comparison for me as a greenhouse manager to compare a newer and more sophisticated system with an older system.”

Finding the silver lining

The final result of the tornado that ripped through campus that fateful September day is a collaboration that has yielded a custom greenhouse complex that will serve its purpose and play an integral role in the continuing development of agricultural research in the years to come. “We’re getting more growing and research space, a much higher level of technology and efficiency than what we had before,” Jones says. “It has been a good example of making lemonade out of lemons, and really gave us an opportunity to expand into a facility that we really needed to be on the cutting edge of research.”

Photography by Jennifer M Photography except where noted

Explore the December 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners