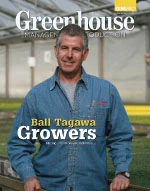

Ball Tagawa Growers was the first plug grower outside the cut flower industry to receive VeriFlora certification. Site manager Steve Sapone said the certification process helped the operation become more efficient.For a better part of a decade, Ball Tagawa Growers in Arroyo Grande, Calif., has taken a proactive stand on environmental issues such as energy efficiency and water recapture. Although the plug and liner grower is located in a state with rigorous environmental regulations, general manager Dave Pruitt was going beyond the minimum requirements.

Ball Tagawa Growers was the first plug grower outside the cut flower industry to receive VeriFlora certification. Site manager Steve Sapone said the certification process helped the operation become more efficient.For a better part of a decade, Ball Tagawa Growers in Arroyo Grande, Calif., has taken a proactive stand on environmental issues such as energy efficiency and water recapture. Although the plug and liner grower is located in a state with rigorous environmental regulations, general manager Dave Pruitt was going beyond the minimum requirements.

During a fortuitous meeting with Michael Keyes, a certification manager for Scientific Certification Systems, Pruitt realized his operation was on track to satisfy all the requirements needed for VeriFlora certification.

“Michael Keyes stopped into our facility in 2006 on his way to another grower,” said Steve Sapone, site manager at Ball Tagawa. “Michael was lost and needed directions. And after a short visit, Dave knew that we could achieve certification. At that time, only cut flower growers were certified.”

Sustainability leader

Ball Tagawa blazed a trail for other greenhouse growers of container-grown crops to reap the benefits of VeriFlora certification.

The company received its certification in July 2007. Each year Ball Tagawa Growers is inspected and recertified.

Parent company Ball Horticultural Co. has put a lot of emphasis on sustainability during the last few years, making VeriFlora certification even more important. Certified EcoSource by Ball is a program that provides its customers the option of buying their products from a special group of certified suppliers.

“Certification is good for customer relations. It shows we’re trying to make a difference and we have a third party to back up our claims,” Sapone said.

| Ball Tagawa Growers Founded: In 1991 as a partnership between Ball Horticultural Co. in West Chicago, Ill., and Tagawa Greenhouses in Denver, Colo. Location: Arroyo Grande, Calif. Crops: Plugs, as well woody liners for Ball Ornamentals. Production space: 200,000 square feet covered and 100,000 square feet of outdoor production. Employees: 40 year-round and 60 at peak. Sustainability highlights: Integrated pest management; 35 acres of greenspace that can’t be developed; landscape buffers; all water is recaptured; almost all greenhouses use passive cooling; use of Ellepots and Fertilpots; reusable rack shipping system made of recycled materials. |

As a leader in sustainable crop production, many growers look to Ball Tagawa for inspiration and advice.

“Some of our customers have become VeriFlora certified, which really helps with the supply chain,” Sapone said.

VeriFlora certification requires the operation to keep track of everything and maintain good records.

“The certification process helps you pay close attention to how you’re doing business. It’s good for improving efficiencies and quality, and it helps save money,” Sapone said.

The elements of sustainability

VeriFlora maintains specific elements of sustainability from production to community benefits.

Element 1 is sustainable crop production which includes: pest and disease management; “agro-ecosystem health” which deals with soil fertility and conservation, erosion control and soil quality; and crop management.

Ball Tagawa practices integrated pest management and uses beneficials where appropriate.

“We’re testing more beneficials in different areas,” Sapone said. “The problem we ran into in the past is plants aren’t here for very long on the plug side. But since we’ve picked up woody liner production, they’re here longer and we can use the beneficials more on that crop.”

Natural populations of beneficials show up in the greenhouses thanks in part to the native plants around the facility’s buffer zones.

Ball Tagawa also uses low-volume sprayers and chemicals with low re-entry intervals.

The water and soil are tested weekly to monitor pH and electrical conductivity. And crop times and germination rates are monitored to reduce shrink.

Element 2 is ecosystem management and protection, including habitat management and protection, as well as mitigation and set-asides.

Ball Tagawa is surrounded by 35 acres of greenspace that can’t be developed. Landscape buffer zones around the greenhouses provide habitat for wildlife, including quail and other bird populations and rabbits. Water from catch basins is used to irrigate the buffer zones.

Element 3 is resource conservation and energy efficiency, which covers water resource management, energy resource management and packaging resources.

At Ball Tagawa, all water is recaptured. This is a process Pruitt instituted in 2005. The company is installing more drip irrigation where appropriate to reduce water use. It uses Raypak high-efficiency boilers to reduce energy costs. When it’s time to replace the polyethylene film covering the greenhouses, energy-saving infrared film is installed. Almost all of the greenhouses use passive cooling. Ellepots and Fertilpots are used for propagation to cut down on plastic containers.

Ball Tagawa uses shipping boxes that are made of at least 50 percent recycled material. And Pruitt created a recyclable rack by reusing pallets, wood and plastic. It cuts down on the amount of cardboard used in shipping, which helps keep it out of the landfill. Some growers return the racks to Ball Tagawa for reuse.

High tunnels are used for growing stock plants. Ball Tagawa expects to add more before the end of the year.Element 4 is integrated waste management, including proper disposal or recycling of hazardous chemicals and containers.

High tunnels are used for growing stock plants. Ball Tagawa expects to add more before the end of the year.Element 4 is integrated waste management, including proper disposal or recycling of hazardous chemicals and containers.

Wood, cardboard and green waste is recycled at Ball Tagawa. Extra soil that can’t be reused in the greenhouse is used in stock beds instead of ending up in the landfill. Chemical containers are triple rinsed and recycled by a local chemical supplier. The lunchrooms are equipped with recycling bins for bottles and cans.

Element 5 is fair labor practices, which covers workplace conditions, hiring practices and access to services for workers and their families.

Ball Tagawa employees are offered health and dental insurance, as well as participation in a 401(k) program.

The company implemented an open-door policy for all employees and a suggestion box is located in the lunch room. And monthly birthday celebrations and company parties are a welcome diversion.

Element 6 is community benefits, such as providing community support and demonstrating economic viability.

Ball Tagawa strives to source supplies locally. It takes an active role in Cal Poly’s (California Polytechnic State University) and the local high school’s horticultural programs.

The company participates in the American in Bloom community beautification program by donating plants and soil, and is a member of the Central Coast Greenhouse Growers Association.

In conjunction with the association, Ball Tagawa hosts an open house every April.

“It’s a huge event,” Sapone said. “We sell plants directly to the public, and a percentage of sales go to a scholarship fund. We even bag and sell some of our excess soil from the sowing line — the public loves it.”

Element 7 is product quality, including reducing losses.

Quality control may seem like a no-brainer, but VeriFlora certification helps improve plant quality.

“Product quality is monitored from the sowing process and sticking line to the day it ships,” Sapone said.

There are several reports generated throughout the process, such as germination reports and crop ratings.

“Crops are given a grade each week with a rating of one to five — five being the best. We were doing this even before certification,” Sapone said. “It gives our customers confidence that they’re getting the best quality possible.”

For more: Ball Tagawa Growers, (805) 481-7526; steve@twcg.com. VeriFlora, www.veriflora.com.

Explore the December 2009 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- North Carolina Nursery & Landscape Association announces new executive vice president

- Plant Development Services, Inc. unveils plant varieties debuting in 2025

- Promo kit available to celebrate first National Wave Day on May 3

- Applications now open for American Floral Endowment graduate scholarships

- Endless Summer Hydrangeas celebrates 20 years with community plantings

- Invest in silver

- Garden Center magazine announces dates for 2025 Garden Center Conference & Expo

- USDA launches $2 billion in aid for floriculture growers