Head orchid grower Mike Ferguson said the biggest cultural challenge to growing phaelanopsis orchids is maintaining a very steady environment with minimal fluctuations.Operating 90 acres of greenhouses has led Green Circle Growers in Oberlin, Ohio, to look at ways to automate while being as sustainable as possible.

Head orchid grower Mike Ferguson said the biggest cultural challenge to growing phaelanopsis orchids is maintaining a very steady environment with minimal fluctuations.Operating 90 acres of greenhouses has led Green Circle Growers in Oberlin, Ohio, to look at ways to automate while being as sustainable as possible.

“It really started back in 1968 when John van Wingerden made the commitment to build greenhouses that could reclaim water,” said facilities manager Todd Metevia. “As John’s sons have become more involved with the company within the last several years, they have taken the concept of sustainability more seriously. It’s just smart business. And more retailers are putting an emphasis on being more sustainable.”

One of the most recent additions to Green Circle’s efforts to automate and to be more sustainable was the installation of five Vyncke biomass boilers.

Metevia said that the decision to look for an alternative fuel source occurred about three years ago when the price of oil hit $150 per barrel. Even though the company burned 80 percent natural gas at the time, the van Wingerdens knew the price of fuel was going to continue to increase.

Initially, the company installed a high pressure biomass steam boiler.

“Because it was high pressure, the company was required by the state to have a full time person on staff to operate it,” Metevia said.

The new Vyncke boilers are low pressure so no full-time operator is needed. The boilers are tied into the company’s Priva environmental control computer as well as being monitored by Vyncke at its headquarters in Belgium.

The primary fuel for the boilers are wood chips. Green Circle has contracts with local tree service companies to deliver wood chips which are stored in a 500- by 75-foot hoop structure that can store 250 truckloads of chips. Each truckload, which holds about 100 cubic yards, costs about $900. During an average 24-hour period, one boiler burns about 300 cubic yards.

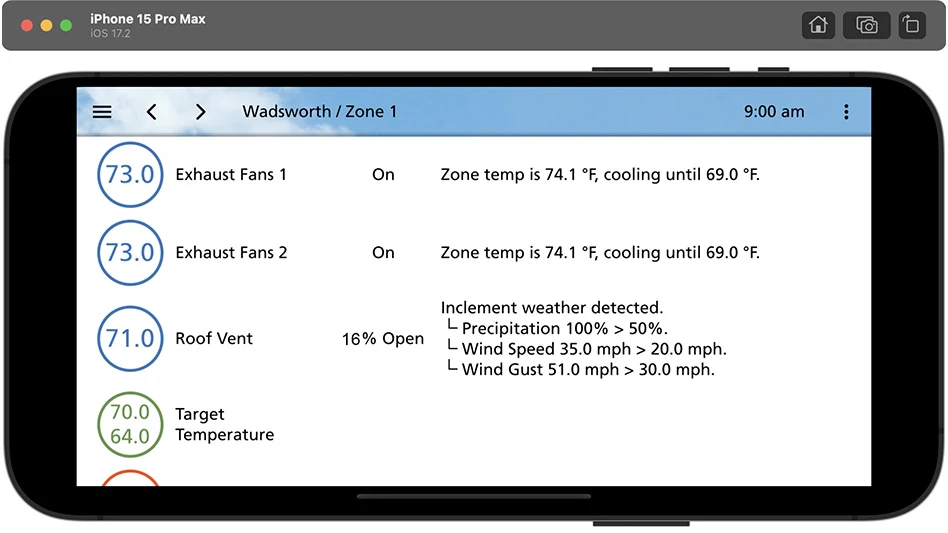

Heat generated by the boilers is used to heat water in two water holding towers. One of the towers holds 1 million gallons of water and the other holds 800,000 gallons. The Priva computer allows the company’s employees to monitor the boilers and the water towers to ensure maximum operating efficiency.

Minimizing fluctuations

Having the ability to better control its fuel costs with the installation of the biomass boilers, Green Circle has added a crop that few northern growers would consider producing — phalaenopsis orchids. The company currently has 5 acres dedicated to orchid production in its Just Add Ice program. It worked with the Dutch company SO (Smaal Orchid) Natural to build a facility based on a European production model. Green Circle is also partnering with Mid-American Growers in Granville, Ill., to grow orchids for the Just Add Ice program.

The Prins Venlo-style high tech greenhouses are equipped with an outside curtain that is used in the summer during high light periods along with two inside curtains, one primarily for shade and the other for energy savings. Priva climate optimizers are located under the growing tables to provide the proper production temperatures year-round. A floor heating system and a pipe system in the upper portion of the greenhouses provide additional heat and humidity control.

Head orchid grower Mike Ferguson said the biggest cultural challenge is maintaining a very steady environment with minimal fluctuations.

“We have a very tight temperature range that we are trying to maintain as well as the humidity range and light levels,” Ferguson said. “We have numerous sensors along with the Priva computer system that allows us to narrow in on the perfect climate.

“We have a very tight temperature range that we are trying to maintain as well as the humidity range and light levels,” Ferguson said. “We have numerous sensors along with the Priva computer system that allows us to narrow in on the perfect climate.

“The weather here is much more extreme than the conditions in Holland. Our climate control strategy is different especially during the transitional times of year between seasons.”

On average each crop takes about 45 weeks. Ferguson said that during the winter the flowering period takes a little longer even though the light levels are supplemented with 1,000 watt high pressure sodium lamps.

Green Circle started growing the orchids in March 2008 and harvested its first crop for Valentine’s 2009. The company is now finishing over 20,000 pots per week with plans to do larger promotions for Valentine’s and Mother’s Day. The company is also looking to do other promotions such as Back-to-School and Christmas.

Specialized production

All of the orchids are grown in specially-designed, transparent 12-centimeter pots containing a customized pine bark-based substrate. Currently, the pots and substrate are imported from Europe. Although planted by hand, the pots are automatically inserted into a transparent vase cup, spaced on tables and moved into the greenhouses by a F-W Systems automated handling system.

Because the orchid roots can photosynthesize, both the vase cup and pot are transparent. The vase cup keeps the orchid vertically oriented so that plants can be spaced closer on the tables. The V-shaped leaf orientation also aids in directing water from overhead irrigation booms down and into the substrate. SO Natural holds the patent for the re-usable vase cup in Europe and Green Circle holds the North American patent.

“SO Natural is working with both Green Circle and Mid-American Growers to get us on the same level, using the same climate strategies, the same components and the same inputs”, said Ferguson. “We (Green Circle) will be producing just over 1 million orchids annually in a 5-acre area. Mid-American, which has retrofitted a structure for its orchid production, will be producing slightly fewer orchids in a marginally smaller growing area. The goal is to grow plants here in Ohio and in central Illinois that look like the exact same product and that you won’t be able to differentiate between the two.

“Our current planting density is probably higher than any other American grower. We are trying to maximize the output for the area we are producing in,” he said.

Since there are no aisles in the orchid greenhouse, Ferguson uses overhead booms to move above the tables to inspect plants.

“I check plants in each bay every day,” he said. “Scouting multiple spots in a single bay is part of my daily routine.”

To ensure even more control over its orchid crop, Green Circle has constructed an additional 3-acre greenhouse that will be used specifically to produce starter plants in open trays from tissue culture flasks brought in from SO Natural. Ferguson said the young plant growth phase is about six to eight months long.

“With such a long-term crop, we don’t want anything to retard the growth of the plants or cause them to have a slow start,” he said. “If there are problems starting out, there will be unevenness and delays through the rest of the growing cycle.”

For more: Green Circle Growers, (440) 775-1411; www.greencirclegrowers.com.

Explore the January 2010 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Star Roses and Plants introduces Martha Stewart Rose

- Hoffman Nursery announces David Hoffman as CEO, Craig Reynolds as COO

- Plantpeddler releases Poinsettia Variety Day 2024 results

- Sarisa insecticide now registered for drench applications and many common greenhouse vegetable crops

- Ball FloraPlant launches redesigned website

- Costa Farms wins Top 10 Marketing Team at 2024 OnCon Icon Awards

- Thank you(!)

- Construction begins at Dramm’s Fish Fertilizer Facility in Wisconsin