|

The word sustainability has been used a lot during the last few years. The horticulture industry has seen a major influx of organic production methods as well as organic and organic-based fertilizers that tout their benefits as being “safer” for the environment. In many instances this may be true, but in regards to nutrient quality, delivery and uptake by plants, there are several ways to modify the use of conventional fertilizers to increase grower sustainability without going truly organic.

Reducing waste

Implementing fertility best management practices (BMPs) is an easy way to become more efficient, effectively reducing waste in many areas (energy, nutrient and plant loss, time and money). In choosing the proper BMPs, it is essential to maintain plant quality. Implementing BMPs while skimping on the details may make you feel more efficient, but in the end you will lose customers and money.

BMPs have been suggested as guidelines for continual improvement in order to make growers’ routines more efficient, less wasteful and less impactful on the environment. There are several BMPs that apply to the use of water soluble fertilizers.

Water appreciation

Paying attention to all things water in your operation is by far the most important concept to grasp. Irrigation methods, timing, watering cycles and leaching fractions are factors that are unique to each grower.

Each irrigation method (drip, sub-irrigation, ebb-and-flow and overhead) can be evaluated to apply improvements that control the amount of water used. Control of irrigation to provide plants with a uniform amount of water for a specific period of time helps realize improvements using both water soluble and controlled release fertilizers. When used correctly, a significant reduction in the overall amount of water and fertilizer required to produce quality plants is observed.

Increased leaching promotes nutrient loss and runoff as well as increasing the amount of time actually watering. A decisive watering and fertilizing schedule based on indicators such as growing conditions and plant water status is a more effective way to ensure plants are receiving and using the nutrients applied. Reducing the “leaching fraction” (the amount of water lost after an irrigation event) decreases nutrient runoff and money down the drain.

Deliberate hand watering, appropriate placing of drip tubes in the root zone, capillary mats, computerized overhead booms and ebb-and-flood floors and benches are just a few irrigation methods that can be implemented to minimize the amount of water lost from each pot. Managing a minimal leaching fraction as well as being aware of the nutrient balance, pH, electrical conductivity and alkalinity of the water applied daily allows growers to make decisions that are more efficient and less impactful on the environment.

Fertilizer selection

Water soluble fertilizers have been around in one form or another for a long time. All water soluble fertilizers are formulated based on the same numerical calculations. The formulas can be manipulated by controlling the nutrient sources and percentages in a 25-pound bag formula. What differentiates products or brands are the science, quality and design behind the products. This is where growers can incorporate BMPs into their environmental plan.

Matching water quality to the fertilizer selection helps in two key ways:

- Understand and optimize the initial water quality.

- Spend wisely on the best fertilizer formulas for growing high quality crops.

Purposeful fertilizer selection allows for the most precise nutrient balance going into the plant so that growing requirements are met and little fertilizer is left behind or lost. However, this is not a “one-size-fits-all” recommendation. What works for one grower may not work for another.

Careful consideration of growing plant species, varieties, growing media, type of container and size, and environmental conditions play a large part in fertilizer selection. Using the technical support of a local extension agent, analytical laboratory or fertilizer manufacturer can help you dial in the fertilization specifics for your operation.

Efficient by design

Some of the newest, cutting-edge technology in fertilizer design takes into account the above concepts and the desire to reduce overall fertilizer use. As fertilizer prices skyrocketed in 2008, there was a need to evaluate some formulas to ensure they were delivering balanced nutrients as well as taking advantage of some cost savings.

Some fertilizer formulations were designed more than 30 years ago. Since then, there have been significant changes and improvements in the type and quality of the raw materials available for fertilizer blends.

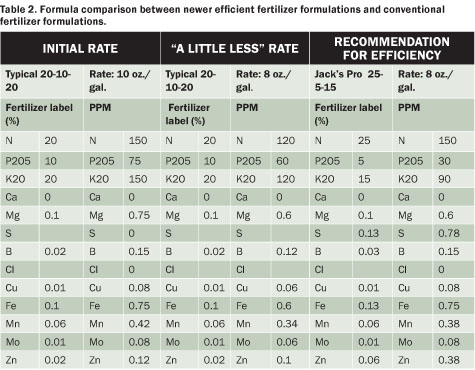

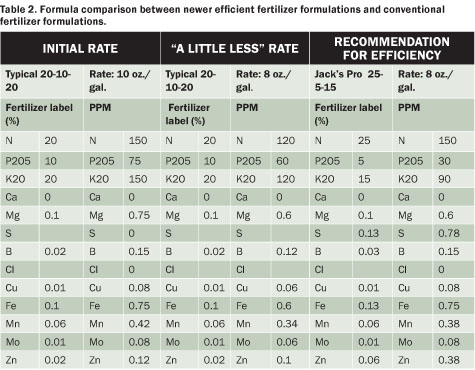

Growers are feeding less to save some money. The effect of this practice initially saved the growers money. However, lab testing showed an increase in key secondary and micronutrient imbalances causing costly single element corrections. This cost growers more due to lower-quality plants and lost time and money.

With the introduction of new efficiently designed fertilizer formulations (i.e., Jack’s 25-5-15 High Performance), significant improvements were made to “old standards” like 20-10-20. The new formulas deliver the nutrients in a balanced package for optimum uptake and availability to the plants.

Better fertilizer formulations

The following are some highlights of more efficient fertilizer formulations.

- Higher nitrogen formulation with well-balanced secondary macro- and micro-nutrient levels reduce fertilizer use while still ensuring optimal plant growth/health.

- Contain a lower percentage of ammoniacal-nitrogen (43 percent) than other acidic fertilizers: 21-7-7 (90 percent), 20-8-20 (60 percent), 20-20-20 (70 percent), 18-9-18 (48 percent) reduces the chance of ammonium toxicity to crops.

- Balanced micronutrient levels comparable to peat-lite formulas.

- High potential acidity (608 kilograms calcium carbonate per ton of fertilizer) helps to keep the growing medium pH low when irrigating with high alkalinity water.

- Can be used for a quick green up of overall deficient or underfed crops.

- Overall fertilizer cost savings of between 25-45 percent compared to standard 20 percent formulations.

- In addition to fertilizer cost savings, reduced fertilizer use results in decreased labor, decreased mixing and decreased handling of fertilizers and reduced shipping charges.

These similar type efficiencies can be seen in almost every category of fertilizer formulation. Taking the time to evaluate nutrient choices can add up when it comes time to paying the bills. However, remember that with all water soluble formulations, if the fertilizer is sitting at the bottom of the mixing tank it is not available to the plants.

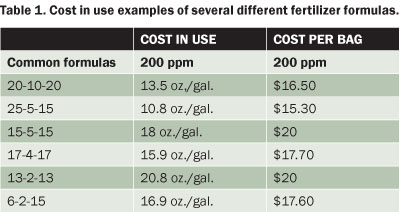

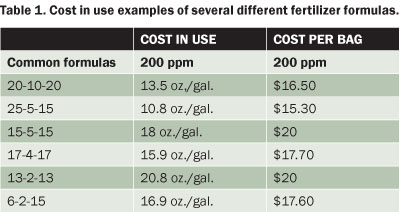

Information like “cost-in-use” comparisons are one of the most under utilized tools in fertilizer selection. These BMPs can allow for environmentally conscious decisions that end up with real time cost savings.

Cari Peters is vice president, J.R. Peters Inc., (866) 522-5752, Ext, 14; caripeters@jrpeters.com; www.jrpeters.com.

This article is adapted from the presentation “Water Soluble Fertilizers: Best Practices for a Safe Environment” at the 2010 Northeast Greenhouse Conference & Expo (www.negreenhouse.org).

|