“Direct to your doorstep every month” is pretty much the retail mantra of the moment; one that holds true for the plant industry as much as any other. I’ve lost count of new online direct-to-consumer houseplant retailers that keep popping up. All that marketplace pressure, or opportunity, may have you considering shipping direct to retail customers.

With the houseplant craze still on the rise — and market disruptors such as The Sill influencing many entrepreneurs from outside the green industry to jump on the plant wagon — growers are faced with the decision of going retail to compete.

On the surface, or from the outside, it may seem like a simple enterprise to start direct shipping the plants you’re already growing. Not so. You’re creating a new profit center for your operation, which is often akin to creating an entirely new business. A new business that has very different logistical requirements than your wholesale operation. Online ecommerce capacity, inventory tracking, taxes and accounting, order pulling, packaging, shipping and so on. All these new operations require different and additional labor and costs.

If you think it’s just the logistics you’ll need to adapt and manage, think again. The marketing work that will go into targeting and engaging with the end consumer will be a whole new ball game for you. Oh, and you’ll need to staff for that work too.

Direct shipping isn’t going to be logical or profitable for all wholesale growers. For some, it could mean creating the new customer base and revenue stream they need to stay in business. Let’s look at a few fundamental considerations if you find yourself facing this decision.

Product

Before you consider going the direct-shipping route, consider your products and plant offerings. Is what you grow going to be in-demand for online plant shoppers? For example: If your current customer base is landscape contractors and your product cash cows are mostly full-flat bedding annuals, then online direct to consumer sales may make no sense for you.

If your product selection is more diverse across plant categories or unique, and you’re willing to mix and match flats and sell individual plants, then branching out into retail sales can make sense. If you are a tropical foliage or succulent grower, then your inventory is a prime target for today’s online plant consumers.

Technology

Selling product as an online retailer is going to require not only a nice modern website, but also a meaningful investment in an ecommerce platform, as well as integration with your existing inventory software and live inventory itself. Creating a new digital presence may already be a big step for you.

Legal

Obviously, there are different legal and monetary considerations when selling retail versus wholesale. Additional business licenses or certificates may need to be obtained. Taxes will need to be collected and reported differently, dependent upon where you ship. You’ll also have to make sure you manage shipping restrictions for certain types of plants across state lines.

Marketing

You’ll be creating a new profit center for your business; you should also create a new business plan or marketing plan to support it. Are you ready to start marketing to an entirely separate segment of customers? Defining exactly who you’ll be selling and shipping direct to is vital to creating effective targeted marketing. You’ll need to tailor both organic and paid marketing and advertising efforts to your new customers, as well as manage your social media engagement.

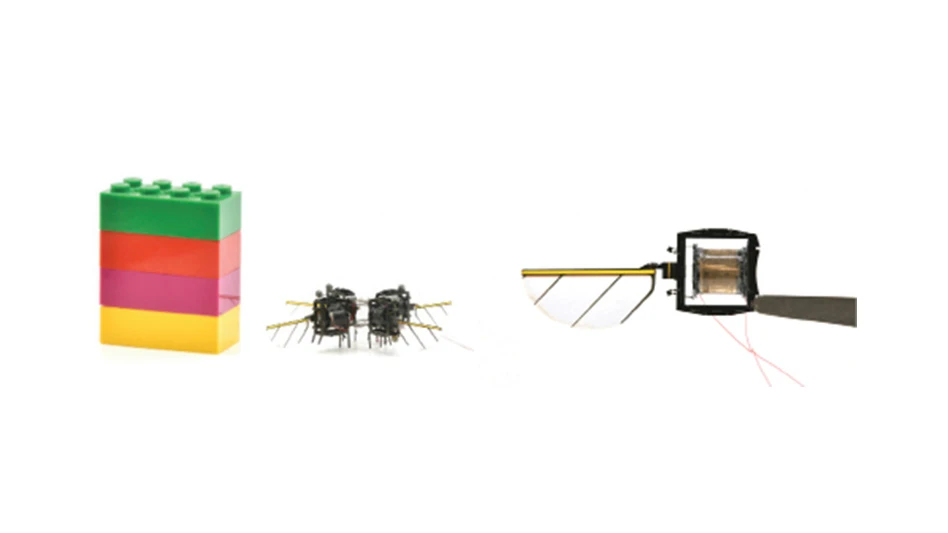

Packaging

If you’ve ever ordered plants online or from a mail-order business, you’ve probably seen all sorts of different packing styles. Some work great, some are terrible and result in damaged plants. Figuring out how to properly pack your plants so that they not only survive their shipping journey, but also show up looking fantastic, is no easy feat. You’ll need to do a lot of experimentation and invest in the right materials configuration. Not to mention, create new customer facing POP materials, such as tags, care sheets and more.

Labor

All the work that goes into shipping direct to customers will differ from your wholesale SOPs. If your sales have been declining, and your existing staff has time to burn, then it could be a good opportunity to put them back to work and grow sales. If you’re already maxed out on your labor, then you’ll need to plan for new staff to handle customer service, process retail orders, assemble orders, pack and ship, and do marketing. Don’t assume your existing wholesale staff will be able to add on retail duties or be suited to them.

Outsourcing

You may have seen a few plant “drop shipping” services pop up over the last few years. These operations plug in to your ecommerce platform, such as Shopify, and drop ship plants they grow to your customer. While I think this kind of model could potentially be useful for retailers that are not in the green industry (but want to retail plants) — or retail garden centers who don’t want to take the direct ship plunge but want to capitalize on certain retail plant trends — you are giving away a lot of control. Whatever, and however, the drop shipper handles product quality and customer service will be a direct reflection on your brand. Be prepared to keep a tight eye on quality control if you outsource your online plant sales.

We’re only scratching the surface here, as there are many other factors to consider when you’re developing a new profit center for your greenhouse operation. Direct shipping may not be right for you as a grower, but if you’re ready to jump in, just make sure you’ve done all your retail homework.

Explore the January 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Meet the Next Gen: Gabriella Blair, Star Roses and Plants

- Leading Women of Horticulture: Katie Dubow, Garden Media Group, and Aubry Field, Lizzy Blossom

- Showing up at your horticulture business as your whole self

- Leading women of Greenhouse Management

- USDA fires experts on invasive pests, including Asian citrus psyllid, chilli thrips

- Farwest Show calls for 2025 New Varieties Showcase entries

- Leading Women of Horticulture: Arden Pontasch, North Creek Nurseries

- Leading Women of Horticulture: Emily Showalter, Willoway Nurseries