The challenges facing greenhouse and other indoor growers are daunting, especially as you consider the macroeconomic impacts that have increased pressure to lower operating costs and improve the environmental footprint without negatively affecting the growing product. Record inflation and supply chain issues that have been commonplace look to continue in the immediate future. Add it all up, and growers are being pinched from many directions.

One area where significant advancements are being made to reduce costs and improve energy use is in lighting technology, specifically LEDs. The indoor professional horticulture industry (ProHort) has been at the forefront of LED lighting as an alternative to high-pressure sodium (HPS). However, within the past year, LED lighting technology for ProHort has advanced further. Interestingly, the licensed U.S. cannabis industry has played a big part in helping to drive improved LED lighting for ProHort.

Because cannabis is a high-value crop, its stakeholders have invested heavily in research and development to solve for the spectrums of light cannabis needs to grow while enhancing sustainability of indoor cultivation. This has led to innovation such as Hawthorne Gardening Company’s patented Gavita CT1930e LED fixture that generates 5% more light output than its traditional HPS lights while using 20% less energy (comparing umol output and wattage, respectively).

This type of R&D in cannabis cultivation has informed technology for ProHort in the form of Hawthorne’s new Agrolux Wega LED product line, which is in high demand in North America and Europe because it enables growers to achieve higher light levels, higher efficiency and enhanced spectrum control that are not possible with HPS lights. These new lighting functionalities create opportunities to grow a wider variety of crops more efficiently with artificial lighting. Tomatoes, cucumbers, bell peppers, eggplant, strawberries and other berries are known to benefit from LED lighting. This newer LED technology also addresses a major grower concern — crop consistency, which directly benefits from Hawthorne’s patented high-efficiency optics technology developed for the CT1930e. The Wega achieves fixture high-efficacy and uniform light distribution simultaneously and can contribute to additional energy savings versus legacy HPS lights.

So where do we expect things to head? Growth in indoor ProHort is outpacing outdoor by 20% annually, fueled by a worldwide need for locally and sustainably produced food and to grow more efficiently on available agricultural land to serve higher populations. We know growers are increasingly convinced of the economic benefit to use higher levels of artificial lighting. That’s why it is incumbent upon our industry to continually innovate and develop versatile LED lighting options.

We also need to do more to incentivize growers to adopt more efficient LED lighting. Local utilities in many states offer energy rebates, but more can be done to work with government regulators to explore additional incentives.

Hawthorne is committed to helping drive this change, including through ongoing R&D and by working with growers to test new possibilities with LED lighting. The future of ProHort is bright, and the technology to overcome challenges to its growth are making a difference.

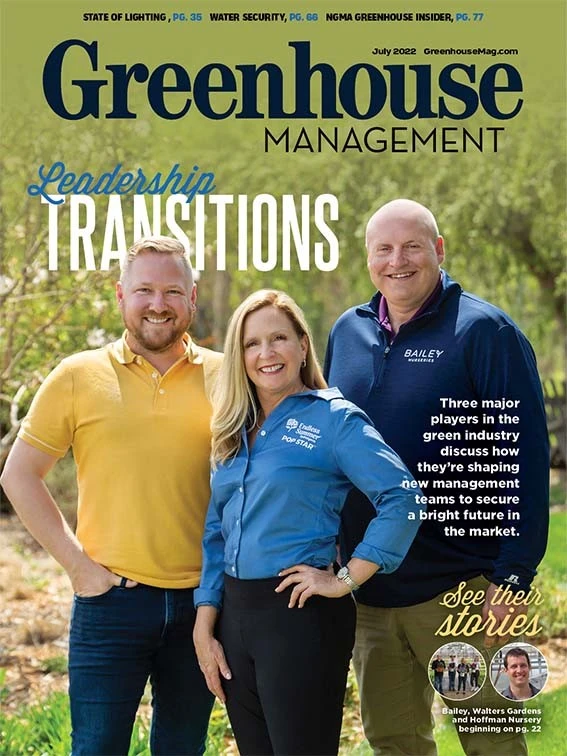

Explore the July 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Tony Abbas named vice president of sales and business development at Prospiant

- Grant awarded to test western U.S. wood species for use as wood fiber potting substrate

- Pennsylvania Horticultural Society announces 2025 Gold Medal Plant winners

- GIE Media Horticulture Group wins five regional 2025 Azbee Awards of Excellence

- Terra Nova Nurseries introduces rust-free and disease-resistant heucherella

- John T. Nickel, founder of Greenleaf Nursery Co., passes away at 89

- Three tours offered at 2025 Farwest Show

- Garden Media Group announces sixth annual Women in Horticulture Week