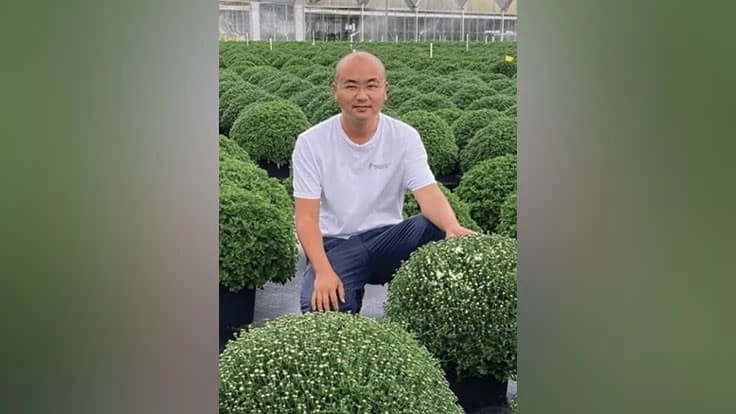

A self-proclaimed “plant guy,” Miao Wang developed a passion for horticulture at a young age. Growing up in China, he started collecting succulents around age 6 — fascinated by the varying colors, shapes and textures of the leaves. When his parents explained that succulents didn’t need much care, he began to fill his room with different varieties of echeveria, sansevieria and sempervivum.

“I always wanted to be part of the horticulture industry, since I was a kid,” says Wang, who earned a Bachelor of Science in Agriculture in China in 2012, and then came to the U.S. to earn his master’s degree in horticulture at Stephen F. Austin State University in Texas.

After completing his education in 2014, Wang worked as assistant grower at Seville Farms for about two and a half years before landing the head grower position at Green Lake Nursery outside of Dallas in June 2017.

“I love growing plants, and plants bring me a lot of happiness, so it’s a blessing to work in this amazing industry,” he says. “It really doesn’t feel like a job most of the time. It’s my hobby and my destiny.”

Improving efficiency

Since bringing his plant passion to Green Lake, Wang has helped the nursery double its production of succulents. By applying his experience as a grower — both from his personal collection and his professional work — Wang has helped the nursery improve its growing processes to benefit all of its crops, which span 1,500 varieties of more than 600 species.

“I always look for ways to grow better plants and improve efficiency,” he says.

When Wang started working at Green Lake, most of the watering was done manually — even though the nursery owned automatic irrigation equipment. With manual labor, “you can’t guarantee that every pot will receive the same amount of water or fertilizer,” he says. “That caused inconsistent performance.”

Particularly, Wang noticed that the quality of mums varied widely across Green Lake’s crop. So, two years ago, he began conducting trials using drip tape irrigation on a few 4-inch mums. Seeing positive results, he moved the entire mum crop to drip tape this year.

“By doing this, the crop uniformity has improved significantly,” he says. “This year, our mum crop is the best it’s been since I came here. They look perfect, and we have very low loss.”

Wang continues to update the growing protocols for plant species in Green Lake’s lineup, which include perennials, groundcovers, grasses, vines, annual color and xeric plants. “My goal is to have as many plants look as perfect as possible,” he says.

Minding the details

Every Monday, Wang’s week kicks off with “grower walks,” where he and his supervisor walk through the greenhouse to meet with each section grower to discuss the plans and priorities for each crop. “We use the color-coded flagging system, so if something needs to be fertilized, it gets blue flags. If it needs to be kept dry, it gets black flags. If it needs to be spaced, it gets red flags,” he says.

In addition to the six section growers on his team who are responsible for watering and fertilizing, Wang also works with a plant moving team focused on spacing, a plant quality team devoted to weeding and a scouting team that looks for insects and disease. With 10 acres under cover, another 10 acres of outdoor production and more expansion planned in the next couple years, Wang needs the whole team working in unison to produce the best plants for Green Lake’s wholesale customers.

But his role as manager isn’t just about assigning tasks in the greenhouse; it’s about helping his growers understand how their individual tasks impact the final product.

“It’s very important to make sure people understand why I make certain decisions,” he says, like when to trim or how much to water a certain plant. “In my role, I need to teach people how to make the right choice every day.”

For example, instead of just telling growers that certain plants need drier soil moisture, Wang will set up small trials to illustrate the impact of different watering levels. “I like to use my own strategy as an example to show why I make certain decisions. After two or three weeks, when they see how good the crop looks, then they will understand my decision,” he says. “If they don’t see it themselves, sometimes they won’t believe you.”

By showing results instead of telling his team what to do, Wang emphasizes the difference that small details can have on a crop. “You have to pay attention to the details to be successful growing quality plants,” he says. “Don’t ignore a small problem, because it can become a disaster and destroy a whole crop if you wait too long to resolve it.”

Explore the November 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners