The purpose of misting greenhouse and nursery cuttings is to prevent leaf temperatures from rising to a point where more water is lost from the leaf than can be replaced through the cut end of the stem. By maintaining a film of water over the surface, it is possible to keep leaf temperatures down and thereby keep internal vapor pressure low. The cooling action of mist arises from the cooling effect of evaporation of water from the leaf surface. In this way, heat from the sun is conteracted and the leaf temperature remains low.

For successful cutting propagation, the misting rate should equal the rate of evaporation. Allowing cuttings to wilt reduces their ability to root. Excess moisture, on the other hand, can reduce the amount of oxygen available to newly-formed roots, reduce soil temperature and cause a drainage problem.

Many devices used to control misting systems can be adjusted to meet a wide variety of conditions. Some of these devices are relatively simple and low cost, while others provide more control adjustments. All are devices that make or break an electric circuit that activates a solenoid valve in the water supply. There are some battery-operated devices that can be used in situations such as high tunnels without electricity or for outdoor growing areas. Some of these have a solar collector to keep the battery charged.

Evaporation simulator

The electronic leaf utilizes a stainless steel screen that simulates a leaf. The screen is located among the cuttings in the propagation bed where it receives the same amount of mist as the plants. The screen activates a 24-volt solenoid valve when the cuttings are dry, and shuts off the valve when they have collected enough moisture. Adjustments can be made in the amount of moisture needed to give proper control.

Program repeating timers

One of the common devices is an electronic program repeating controller. It usually consists of two timers. The first provides the length of the misting cycle from one to 60 seconds. This is the time when the solenoid is turned on to provide mist. The second provides time between the misting cycles and can be from two minutes to several hours. Sometimes a clock or photoelectric switch is included that shuts the system off during nighttime. An example might be to provide five seconds of mist every five minutes from 8 a.m to 8 p.m. Some controllers can be programmed to automatically change to a different sequence during the day to match changing misting requirements. Program timers are available that will control a single zone or as many as 24 zones.

The incorporation of electronics allows additional functions to be included. Multiple zone controls may include the following:

- Variable misting cycles — the misting cycle for each zone can be programmed separately

- On-off — manual control for each zone

- Time extenders — the time cycles can be increased or decreased for special conditions

- Battery backup — all programs are maintained in the memory if power is interrupted

- Surge protection — protects against power line surges

- Pump start relay — activates the pump during the misting cycle

- Indicator lamps — show which zone is operating

Computer control

In addition to the above functions, computers can provide additional features. As most computers incorporate a weather station, weather information can be factored into decision making. Light intensity and duration, cloud cover, evapotranspiration, humidity and temperature can provide a more dynamic input that can estimate the water status of cuttings and adjust accordingly. Water pressure can also be controlled to provide more uniform coverage.

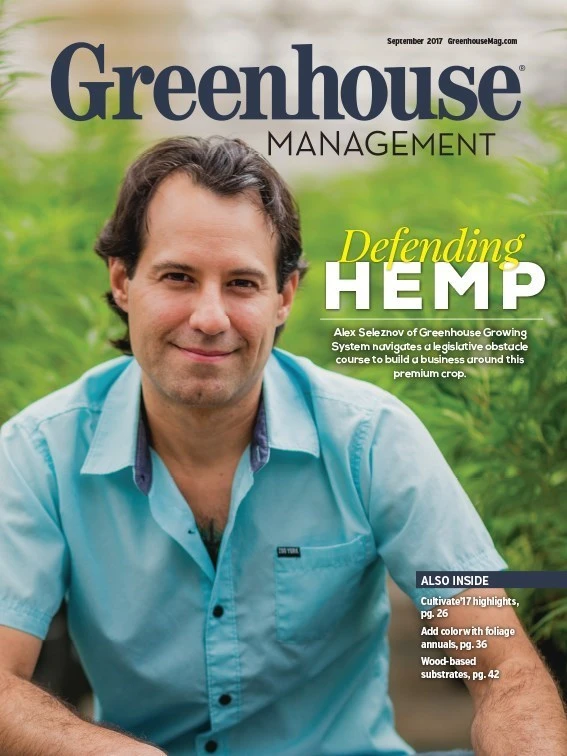

Explore the September 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners