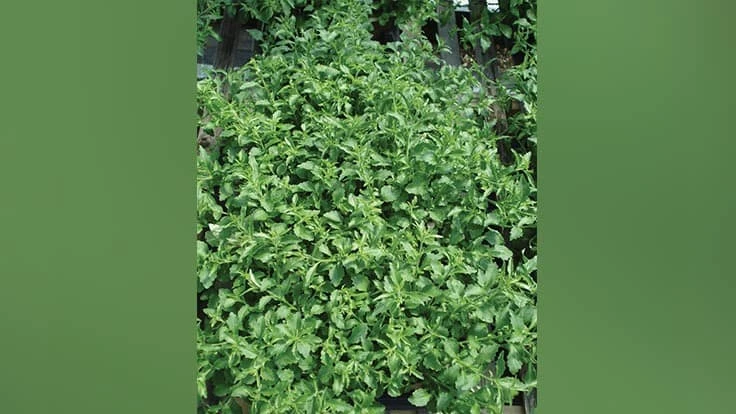

One of the most important responsibilities in growing flowering plants is controlling their growth (Fig. 1), and plant growth retardants (PGRs) are frequently applied for this reason. Liner dips are an easy way to treat different species and cultivars effectively and efficiently. Plug and liner dips work well with nearly any species and container size. They can also be particularly useful for mixed container growth control and can provide species-specific growth control prior to planting mixed containers.

The process

Broadly speaking, a plug or liner dip is placing a tray of young plants into a PGR solution for a short period of time, letting it soak up the PGR, then removing it. However, in order to maximize the effectiveness of your liner dips, there are a few things to keep in mind.

When plug or liner trays are set into the PGR solution, the solution should come up to approximately half the height of the tray. The amount of time a tray should sit in solution varies on several factors, including the volume of solution and how deep a tray is sitting in it, the moisture status of the substrate and the size of the plug or liner. Generally, 30 seconds to two minutes is a sufficient time for a dip to last. A good cue is to wait for the substrate surface to appear to be glistening, indicating sufficient solution has been taken up, as indicated by the saturated substrate. Since the PGR solution is moving into the substrate by capillary action — and not being sprayed onto shoots — the moisture content of will the substrate will affect the application. If liners are bone dry when they are placed into PGR solution, they will absorb too much solution and will suffer from over-application. As a result, stunting will likely occur. A good rule of thumb is to water thoroughly 12 to 24 hours prior to applications so you don’t have overly dry or wet plants going into treatments.

Active ingredients and concentrations

Not every PGR can be applied using liner dips, and only those with root activity can be applied in this manner. The active ingredients suitable for liner dips include ancymidol (Abide, A-Rest), flurprimidol (Topflor), paclobutrazol (Bonzi, Paczol, Piccolo) or uniconazole (Concise, Sumagic). Alternatively, chlormequat chloride (Citadel, Cycocel), daminozide (B-Nine, Dazide) and ethephon (Collate, Florel) cannot be applied using liner dips.

The appropriate concentration to use for liner dips depends on several factors, including the size of container used for finishing, crop vigor, active ingredient strength and finishing environment. Higher concentrations are useful for situations where more growth control is needed, such as smaller finishing containers and/or more vigorous species and cultivars. Alternatively, larger containers and less-vigorous plant materials will require less growth control during finishing.

Just like when drenches are applied to substrate-containing bark, dipping liners propagated in substrate-containing bark will require higher concentrations since the bark can tie up some of the active ingredient and diminish the treatment’s effectiveness.

Unlike foliar PGR sprays, where the greenhouse environment affects the efficacy of treatments by affecting drying time, the environment doesn’t matter when applying plug and liner dips. However, the finishing environment does.

Plug and liner dip applications are made at the very beginning of the production cycle, and subsequent weather that will affect their growing environment is not known. It could be warmer and sunnier than normal, and the liner dip may provide insufficient growth control. Alternatively, a cool and cloudy season may result in a bit too much control. When in doubt, consider erring on the side of lower concentrations for dip treatments. It is easier to come back with an additional spray of a growth-inhibitor later for more control than it is to try and push growth to overcome overregulation.

Take-home message

When using plug and liner dips to treat young plants, there are a few things to keep in mind to maximize the efficiency and effectiveness of applications. However, by remembering some of the best management practices covered in this article, you can save time and money with liner dips.

Explore the January 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners