At Decker’s Nursery, there is one greenhouse that doesn’t look like all the rest. The Groveport, Ohio, nursery is bursting with cutting-edge technology and equipment. But that one house has sentimental value to Brian Decker, third-generation nurseryman and president of Decker’s Nursery. “We didn’t even know where the property lines were, so that’s why it’s so crooked,” Brian says. “It doesn’t have a thing in it. But I just can’t stand to tear it down yet, because my dad and I worked on it for two years on Sundays, bending the steel ourselves.”

Decker’s Nursery, which celebrated its 100th year in business last year, provides local and national retailers and growers with wholesale shrub liners, specialty conifer grafts and finished material. The company was founded in 1921 by Brian’s grandfather, Paul Offenberg, an immigrant from Holland. Paul was a professionally trained horticulturist who had been Royal Garden Advisor for Kaiser Wilhelm prior to the beginning of World War I. The business was named The Paul Offenberg Nurseries, and was located in Columbus, Ohio, where it handled propagation, grafting, liner production, retail landscaping and general retail sales.

Brian’s father, Bernard J. Decker, worked as an ornamental iron and steel worker after he came home from World War II, where he served as a decorated radio operator and gunner in the U.S. Air Force over Europe. He knew his way around the legendary B-17 “Flying Fortress,” but he wasn’t much of a plantsman. In 1953, Paul asked him to join the family business anyway. Brian’s grandfather died a year later, leaving Bernard with the challenge of running the company.

Brian learned lots of valuable lessons from his father, including how to graft plants. Brian had an aptitude for the art from a young age. When he was in sixth grade, he received a Superior rating at the State Science Fair for his project, which focused on grafting and propagation of Hedera helix (English ivy).

In 1979, Brian graduated from Ohio State University with a degree in horticulture and joined his father’s business. It was just the two of them. In 1980, the business was renamed Decker’s Nursery and relocated to its current location in Groveport on a 10-acre parcel.

Bernard grew up during the Great Depression, and like many of his generation, it taught him to live, lean and get by on as little as possible.

“My dad could do everything better than anyone else, so there was no reason to hire anybody or delegate,” Brian says. “It took me a long time to unlearn that.”

But Brian took his education seriously and even then, he was looking for ways to apply what he had learned to improve their business.

“I graduated from Ohio State with a brand-new degree in horticulture and a minor in business, and I was out there with a crew of three guys hoeing weeds for nine hours,” Brian says. “My dad didn’t believe in any kind of herbicide usage or chemical control at all. And he pulled up in his air-conditioned car, and he rolled the window down. And I said, ‘Dad, I didn’t go to school for four years to be out here hoeing out-of-control weeds that are 4-foot-tall when the plants are 6-inches-tall. I’m not going to do this.”

After calling up Dr. Elton Smith, herbicide specialist at the OSU Extension, Brian was able to convince his father to change his ways. It was a triumph of a strong-willed son over a similarly strong-willed father, and it was certainly not the only dispute they had.

“Did we get in arguments? Oh, epic,” Brian says. “There’s still a hole in the office wall where he threw a stapler at me.”

Widening his view

Although Brian says his father, who died in 2012, was an incredible mentor, the two men had different goals for the family business, as well as different methods. Over the years, Brian has seen many nursery owners fall into the trap he always strived to avoid.

“The most dangerous words in the nursery industry are ‘because that’s the way my dad did it,’” Brian says.

Brian joined many trade associations and found incredible value in attending industry meetings. He joined looking to widen his perspective from the small family business he knew. He found that he loved meeting other growers and talking over their shared difficulties and working out solutions. Alan Jones, president of Manor View Farm and member of the HILA Class of 2019, is one of Brian’s good friends. Like Brian, Alan volunteers on many industry boards and committees.

“I’ve heard Brian frequently make this comment about attending industry meetings,” Alan says. “‘I just need to bring back one new idea and I will have covered the cost of the meeting.’”

Brian learned a lot about management, budgets, marketing, staff issues and legislative issues by participating in industry associations like The Ohio Nursery and Landscape Association, American Nursery & Landscape Association, Horticultural Research Institute, International Plant Propagators Society and others.

The peers he met through these groups showed him different leadership methods and helped “calm my rash behaviors,” as Brian says. They also sparked his creativity.

“Brian is an original thinker — sometimes outspoken — who is always thinking ahead to the next project, the next issue and the next solution,” Alan says. “His original thinking can at times cause people to stop and think about what he is proposing and often disagree with him. But that is partly what Brian is hoping to achieve — while you may not agree with his initial suggestion, it gets you to think about the issue from a different perspective and possibly come up with an even better solution.”

In 1993, Brian was starting his term as president of the Ohio Nursery and Landscape Association. As part of the position, he had to write an article each month for the association’s magazine. His father still did payroll by hand. Brian hated the hassle (and bottles of white-out) that came with using a typewriter. He saw this as the perfect opportunity for the business to get a computer. Not only would he use it to type his president’s letters, but he could use it to modernize the nursery in other ways, like accounts payable, payroll, and eventually inventory management software.

Brian’s adoption of technology led to a situation that illustrates the difference between his view and others in the industry. With printer, paper and software advances from the computer, Decker’s Nursery became able to print prices on labels. Brian saw it as a time and labor-saving service he could provide to his customers. But they didn’t all see it that way.

“I said to people, ‘How would you like it if we could put your retail price on your labels so you wouldn’t be sitting out there bent over with a magic marker?’ And you know what they said? ‘Well, then you’re going to know how much our markup is.’”

“‘You know what?’” Brian replied. “‘I hope you make a million dollars selling my plants, because if you do, you’re going to come back and buy some more. I don’t care what your markup is; why are you afraid of that?’”

The hesitation shown by his retailer partners perplexed Brian. Still, Decker’s Nursery has continued to be forward-thinking in its relationships with independent garden center customers. In 2017, the nursery became a grower member of Bower & Branch. For Decker’s, the partnership is a way to reach web-savvy retail customers through Bower & Branch’s online presence. Purchases are fulfilled by growers like Decker’s and buyers have the choice to pick them up at a local IGC or have them delivered.

Early adopter

Brian is one of the American nursery industry’s foremost “early adopters.” Decker’s Nursery is known for embracing technology, from innovative uses of automation in plant spacing, trimming, shipping and more, to installing solar panel systems on the roof of its propagation barn.

History has shown that it can be painful to be first. Early adopters have to fight through issues as new products aren’t always ready for prime time when they hit the market. There are usually bugs to be ironed out and it falls on the early adopters to report them so the product can be improved in its next iteration. A new system may not work as designed, especially once it’s being tested in a “real world” nursery environment with all the dirt, rain and gravel that entails. Typically, in solving one problem, two more may pop up.

Brian dealt with the growing pains of adapting forklifts mounted on motorized trikes to move containers around the nursery. He believed using a pot forks system to handle large quantities of container plants would be beneficial, so he reconfigured everything in his nursery around the use of these trikes, from adjusting openings to hoop houses to allow clearance for the vehicles, to installing irrigation lines that can safely be driven over.

“When he said, ‘We’re going to build greenhouses you can drive through’ ... Holy Moses, what an idea!” Decker’s CEO Mike Miller says.

Even then, Brian had to figure out how to get the fork attachments and the container lips to play well together. It required a ton of trial and error, extra fabricating work and plenty of back-and-forth with container design partners regarding sizes and shapes. And yet, he soldiered on because he believed in the system and what it could do for his nursery.

“This industry is not for cowards or the faint of heart,” Brian says. “You have to go with your gut sometimes and not all accounting data. Large investments often can have unexpected ‘collateral’ benefits. These make black-and-white decisions a rare thing in moving forward. I am also pleased our CEO, Mike Miller, having completed the EAGL program with Charlie Hall, has refined some financial skills to help us see the financial side of these decision more clearly. Combine a clear financial analysis with a fearless desire to succeed and you have a potent combination.”

Sharing what he’s learned

As a fellow, past president (2016) and member of the board of directors since 2014 of the IPPS Eastern Region, it should be no surprise that Brian truly exemplifies the IPPS motto: “To seek and to share.” That spirit is especially important when he shares what he’s learned as an early adopter of technology. He often crafts presentations and gives talks to peers in the industry. As an example, once he’d cracked the code on pot design requirements and fork unit configurations, he shared that information during talks at industry meetings, virtual conferences and more. He doesn’t hesitate to discuss any implements his team created or processes they’ve designed to make production more efficient. Beyond that, he will share the ROI and cost savings of a project or the nursery design requirements that would be necessary to make it work.

Decker’s Nursery extends its sharing to the next generation of horticulture, as well. Each year, the nursery hosts field trips from seven universities. Brian has provided videos showing plant propagation and grafting to these universities at no cost. He also has offered paid internships to dozens of American horticulture students, as well as sponsoring more than a dozen paid one-year International Horticultural Internships through Ohio State University.

Mike Miller took a job at Decker’s Nursery right out of OSU’s horticulture program. He was 22, a farm kid who wasn’t sure what he wanted to do, but knew he wanted to be in wholesale, not retail. “I liked production, not people,” he laughs.

Brian’s drive to educate helped Mike get his start.

“I graduated with lots of knowledge from courses and books, but I didn’t know anything,” Mike says.

Mike stuck around and learned how to grow plants in the real world. Now, he is Decker’s CEO and an important part of the company’s succession plan.

“Brian enjoys showing and teaching people and the industry how we do things,” Mike says. “It’s not just info, he shares on a personal level.”

His candor is refreshing. Brian has always been incredibly open to explaining how something works or why it doesn’t.

“I have learned more from my failures than successes,” Brian says. “Do not be afraid to fail, just be afraid to not try. The industry is consolidating and evolving. We need to stay in the position of lead sled dog or our view will never change. Current problems with labor, political environment, and market evolution make this a challenge. Someone will succeed, but I guarantee you it will not be the folks too afraid to consider new ways of operating.”

Keeping your workforce happy

Brian Decker with some of the NewGen boxwood in production at Decker's Nursery.

Brian Decker with some of the NewGen boxwood in production at Decker's Nursery.When you see a worker at Decker’s maneuvering a trike with its forklift fully loaded with containers through one of the older hoop houses on the property, skillfully weaving back and forth to avoid structural support poles, you understand the amount of training that employee had to have.

That’s why Decker’s Nursery approaches H-2A differently than many growers that use the government-run seasonal worker program. Brian and special projects director Pam Dukes, who (among many other tasks) manages all things H-2A at Decker’s, aim to provide outstanding living conditions for their seasonal workers. Instead of cramming multiple workers into dormitories, barracks-style, Decker’s gives each worker their own bedroom. The housing units at Decker’s have five bedrooms, a kitchen and common area — downright spacious in comparison. There is a waiting list 10 people deep to work at Decker’s Nursery and that’s exactly how Brian likes it.

“When you see the level of mechanization on some of the things we do around here, you say ‘I don’t want to retrain all these people,’” Brian says. “So everybody thinks I’m a big generous guy providing this wonderful kind of environment for these people with the barbecue grills and this and that. But it’s so that people want to come back.”

And it works. When Brian sees one of his extremely skilled forklift operators get off the bus March 1 and go straight to their bedroom, from which they didn’t even take their clothes home for the winter, he knows the investment is worth it. Every H-2A employee is a returnee. The only workers who don’t come back are the ones who aren’t asked back.

The workers appreciate how good they have it. They understand how the conditions differ from other options. They love the privacy of their own rooms and the fact that if they ask their boss for a pool table, they’ll have one the very next day.

“On Sundays, there’s a fiesta kind of atmosphere there,” he says. “You’ve got 15-20 people over here grilling out and drinking beer and playing pool and foosball and watching soccer from home on the big screen TV. I wanted them to have a ‘man cave’ to be able to relax a little bit since they’re away from their families for 10 months.”

Brian recognizes that this is a very different way of approaching H-2A. When he looks at his gross sales, profitability and remembers how he grew up thinking, “there’s no way I could ever pay anybody over $6/hour,” it puts into stark relief how much the industry has changed. Growers who want to survive have to adapt with it. Decker’s Nursery grew revenue 48% during the last two years — the COVID years — as many big nurseries did.

“When you look at H-2A, yes, it’s expensive,” he says. “But what’s the alternative? Local workers — you go through 100 to get one. If you want to expand your business, you need to fill those roles. Could it be better? Definitely. But you need it to have enough people. If you don’t have the things you need to have, your return on investment doesn’t matter.”

The value of your reputation

Brian appreciates everything he learned in his family’s business. But in growing up and moving past the influences of his youth, he had to unlearn some outdated business practices that he assumed were valid. Although he’s changed the way he produces plants many times, he still adheres to the principles handed down to him by his father for maintaining relationships with vendors and customers. Growing the business to what it is today, while still maintaining the respect of others in the industry, has been fulfilling for him.

“I have no worry about anyone accusing our company of anything dishonest,” he says. “This is very important to me; doing business with integrity and grace.”

That carefully cultivated reputation has presented him with business opportunities many times. And when he sees a business opportunity that he believes could be excellent, he jumps in with both feet.

Several years ago, before the blight-resistant Saunders Genetics-developed NewGen boxwood was introduced, Bennett Saunders (fellow HILA class of 2022 recipient) sought out Brian at Cultivate. Because of Decker’s reputation in the industry, Bennett wanted to see the operation in person. Brian hosted several of the brothers and their wives on their way home to Virginia from the Columbus, Ohio, trade show. They were impressed by Decker’s liner production, and they could see the skills they’d heard about were not exaggerated. They talked about the blight-resistant boxwood they’d been developing and wondered if Brian would come to their Virginia nursery to see it. Brian said, “How’s Monday?” This was on a Friday. The brothers justifiably wanted an extra day to prepare, and Brian was sitting at their office at 7 a.m. Tuesday. While he was there, Brian met Paul Saunders, the brothers’ father and patriarch of the nursery. Paul, who passed away in March, shared old IPPS stories with Brian.

“Before I left that day, they had put six or 10 3-gallon boxwoods in the back of my pickup truck without us even having a single signed contract,” Brian says.

Brian knew he needed to move quickly if he was going to ramp up production. Propagation ends Aug. 1 and it was already mid-July. Time was of the essence.

He sterilized a truck and sent it to pick up a full load of Freedom and Independence, the NewGen introductions, from Saunders Brothers right away, so it could make the return trip to Groveport and quarantine in accordance with boxwood blight safety protocols. Once those plants were out of quarantine, Decker’s crew made 25,000 cuttings and it was off to the races. It took a few more months for the paperwork to catch up, but neither side was worried about it.

“They knew our reputation and we knew their reputation,” Brian says. “Because of our skills in propagation and our ability to convince people that we’re the place to go for something like NewGen boxwood or Proven Winners plants — we’re the partner you want to have — because of that skillset, we get the opportunities.”

Looking forward

Decker’s Nursery has been transitioning away from B&B growing for years. Five years ago, you could see rows and rows of shade trees in production. But it takes three or four years to grow a 2-inch tree from a liner. If prices are good when it reaches salable size, you can sell it for $150-$200.

Compare that to the cuttings of New Gen boxwood that fill Decker’s greenhouse bays. Just one of those trays holds 50 plants. Each plant sells for $2.30. That means each tray is about $115. Decker’s is able to turn them in nine months.

“I probably have more money sitting in that quadrant right there than I might have in 25 acres of trees,” Brian says, gesturing at one of the many bays filled with trays holding tiny boxwood plants.

“And it’s a whole lot easier to pick that up than it is to pick up a 2-inch caliper B&B tree.”

In May, Decker’s was expanding its greenhouse production, going from 10 to 16 greenhouse bays. The $1.2 million construction project leaves room for five more bays in the future.

As Decker’s Nursery moves into the next generation of leadership, it will continue to be known nationally as a propagation specialist and new plant introduction source, for e-commerce fulfillment through Bower & Branch, and for finished container production for its regional market.

Brian has three children, all of whom have their own career paths outside of horticulture. With the help of his attorney, he developed an extremely thorough and unorthodox succession plan.

It came about from asking a few important questions. Are your key employees loyal to the point that you would consider them family? If you consider those key staff members family, would you treat them like heirs? If the answer to this question is yes, trust and reward them as family. If the answer is no, change them out for more qualified leadership.

Brian developed a plan to transfer ownership of his nursery to a “core four” group of key employees. (Editor’s note: For a more detailed look at the plan, visit: https://bit.ly/decker-succession.)

“I am amazed at the very high level of performance from our new minority owners since the succession plan was implemented,” Brian says. “I have stopped making 98% of the decisions ... not needed. It is better for the new leadership to make the decisions and the mistakes.”

As his core four take on more responsibilities, Brian is transitioning to working part-time when needed. This year, he took two vacations in spring — previously inconceivable, but made possible through the new ownership plan. He wants to travel more with his wife, Pat, and visit his kids and grandkids. He still plans to participate in industry leadership and mentoring through HRI, IPPS and other activities that steer youth toward horticulture.

“He’s a very lead-from-the-front, tip-of-the-spear type of leader,” Mike says. “My first day, he was the one driving the tractor. He’s the one setting the 7:30 a.m. meetings, but he’s also the one who cooks lunch for everyone after the big propagation push. Or a pig roast after spring rush.”

Despite his success as a leader, Brian hasn’t lost his touch. He keeps the skills sharp that helped bring him so far.

“Brian is unique in that, as a business owner, he still does what he enjoys and is good at within his business — such as joining the grafting crew each winter,” Alan Jones says. “He enjoys grafting much more than attending winter trade shows. But how intimidating must that be for the other grafters to have your boss sitting with you for a couple of months? I’m told Brian makes it a lot of fun, as long as you can graft as fast as he can.”

Explore the July 2022 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Leading women of Greenhouse Management

- Showing up at your horticulture business as your whole self

- Leading Women of Horticulture: Katie Dubow, Garden Media Group, and Aubry Field, Lizzy Blossom

- USDA fires experts on invasive pests, including Asian citrus psyllid, chilli thrips

- Farwest Show calls for 2025 New Varieties Showcase entries

- Leading Women of Horticulture: Arden Pontasch, North Creek Nurseries

- Leading Women of Horticulture: Emily Showalter, Willoway Nurseries

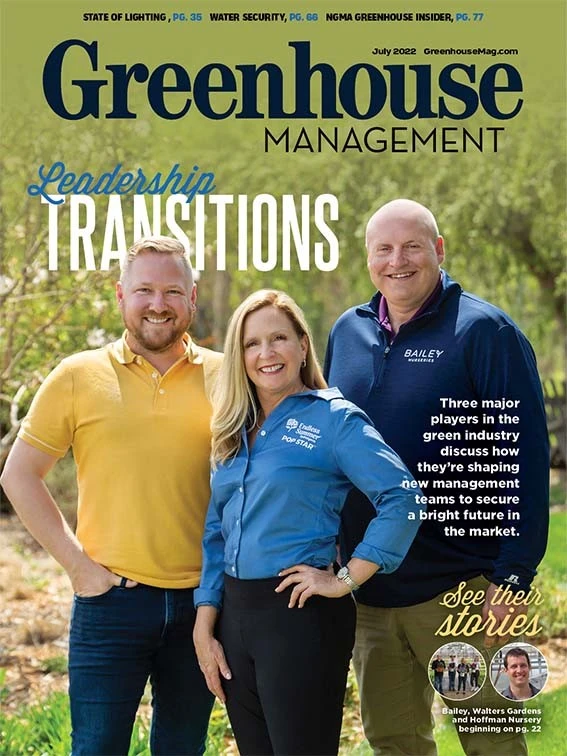

- Leading Women of Horticulture: Anna Ball, Ball Hort, and Terri McEnaney, Bailey Nurseries