The evidence in this trial has been mounting for well over a decade (three decades in Europe), but the verdict remains uncertain for many. Let’s take a look at some of the past and ongoing work in the case of Wood Fiber v. Public Perception and Grower Adoption.

Research trials have been and continue to be conducted on wood-containing substrates across the country at academic institutions, private industry laboratories and numerous grower operations. Data from these trials are slowly becoming public, just as the need and demand for results, observations, recommendations and testimonials have never been higher. While we have some answers about using wood substrates, we find ourselves having as many new questions as we do confirmed answers. Here is some of what we do know and are seeing in today’s evolving production practices and research trials.

Feeding the hunger

Dating back to the early 2000s and confirmed more recently with follow-up trials, it has been discovered that to grow plants in wood substrates or very high percentages of wood in substrates required some significant changes to plant-growing practices. The first of two approaches that were uncovered involved the increase of fertility (fertigation) to the tune of an additional 100 ppm nitrogen in 100 percent pine wood compared to 80:20 peatlite for optimal and equivalent crop growth (Fig. 1A). This was repeated with multiple species including lighter-feeding plants like marigolds or heavier feeders like mums. The extent of nitrogen supplementation that a grower must add depends on 1) traditional fertility practices (standard ppm N applications); 2) percent of wood substrate in the mix; 3) type of wood component; 4) age and properties of wood component; 5) irrigation and fertility delivery method.

When wood fiber is blended with peat at rates as low as 10-20 percent, the two materials interlock, forming a matrix that is now a unified and structured substrate.

The second approach to improving plant growth in wood substrates is to increase the percentage of peat (Fig. 1B). Some of the first trials conducted many years ago showed that plant growth increased at lower fertility levels as the percentage of peat increased. This was not shocking or unforeseen due to the inherent properties of wood versus peat, but what was very interesting was the fact that plants could be grown very successfully at 150 ppm N with rates of wood close to 50 percent. Now, fast forward to today when basically all trials (academic, industry and grower) are conducted with peat:wood blends (not 100 percent wood like a decade ago) and the results often indicate that wood can be amended with peat at rates of 30 to 50 percent with a high level of success. Again, caution is offered, as there are many variables that can make this scenario successful for some and not so successful for others. Rates of wood amendment to peat are still more comfortably recommended in the range of 10 to 40 percent.

The nutrient (primarily nitrogen) immobilization that occurs in wood substrates is still a very complex issue that is very difficult to analyze and quantify. Researchers have tried for decades to devise adequate, simple and reproducible tests to measure nitrogen tie-up, but to date few options are available. One method used in Europe (some evidence that it is occurring here in the U.S. as well on a small scale) is a nitrogen impregnation technique. Wood substrate manufacturers who employ this technique will incorporate granular nitrogen into wood chips prior to processing (extrusion devices). During the thermo-mechanical fiberization (wood chip to fiber) the fertilizer is “impregnated” into the wood fiber (Fig. 2). Upon incorporation of the wood fiber into peat (or other material), no supplemental fertility is needed, as the wood now contains the extra nitrogen needed to compensate for any tie-up activity that may impact plant growth and performance.

Getting physical with peat

Wood can make peat better. Yes, I said it! Wood should not be viewed as a peat replacement or even a major threat to peat producers and/or products. Instead, I offer the idea (after many mistakes and after eating much crow) that wood products can enhance certain peat mixes and create opportunities for new peat-based product development. Look around at what many of the Canadian and European peat producers are doing — embracing wood as a component, while not neglecting the use and promotion of peat. How can wood make peat better or make mixes better? For one, the unique physical marriage of peat and wood fibers is a beautiful thing to witness! When wood fiber is blended with peat at rates as low as 10-20 percent, the two materials interlock, forming a matrix that is now a unified and structured substrate. This is very different than peat and perlite blends, which even after mixing remain forever separate. The union of peat and wood fibers creates a physical environment that is high in overall porosity, high in airspace, has great water capture abilities (less hydrophobic), good drainage properties, good water retention and movement, high substrate humidity, no-splashing or separating or floating during irrigations, and a playground for fast-developing and aggressive roots.

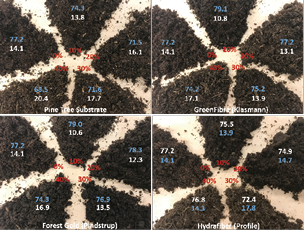

In addition to the “substrate matrix” effect that wood and peat create when blended, the physical environment that they create in regard to water holding and air space percentages is desirable. When blended with 100 percent peat at rates of 10, 20, 30 and 40 percent (by volume), wood fibers (pine tree substrate, GreenFibre, Forest Gold and HydraFiber) show excellent water-holding capabilities as well as increases to air space in the substrate environment (Fig. 3). It has been reported and confirmed over and over that as the percent wood fiber/component increases the air porosity of peat mixes will increase similar to perlite. This interaction is one of the reasons that many growers are adopting wood components in their mix instead of perlite. More will be discovered and revealed relative to the role of wood components as true alternatives to perlite in the near future. The implications here are huge.

The green revolution

Emerging crops are also high-priority areas for substrate researchers and manufacturers. With tremendous growth in controlled-environment food, fruit and cannabis production comes new opportunities for traditional and new substrates that are being released throughout the growing media industry. The number of new mixes (most containing wood and/or perlite-free) released just in 2018 is staggering! The possibilities are endless when one considers not only the immense value of food crops but also the continuing legalization of cannabis (in one form or another) across the country. Some researchers here at North Carolina State University are now fully engaged in cannabis substrate research to assist growers and the substrate industry with substrate-related development and use for this “new” crop (Fig. 4). Expanding and emerging markets for growing media will continue well into the future. Wood fiber, in some form or fashion, is here to stay and now should be considered a viable growing media component and no longer just an “alternative.”

So what’s the verdict for wood fiber? The jury may still be out for some, but others are fully onboard and publicly expressing their excitement and support for the adoption and use of wood substrates (with peat!) as part of their production protocols. So what say you?

Explore the September 2018 Issue

Check out more from this issue and find you next story to read.

Latest from Greenhouse Management

- Proven Winners introduces more than 100 new varieties for 2025

- UF/IFAS researchers work to make beer hops a Florida crop

- CIOPORA appoints Micaela Filippo as vice secretary-general

- Passion grows progress

- Registration opens for Darwin Perennials Day

- U.S. Department of Labor finalizes farmworker protection rule

- Azo Root is now available from Harrell’s

- Bidens ferulifolia Blazing Glory