On a bright, sunny summer day, a 30 x 100-foot greenhouse will gather about 32 million Btu’s of heat. This is equivalent to burning 32 gallons of fuel oil or 320 therms of natural gas. If the greenhouse is full of plants, about half of this heat is used for transpiration and evaporation. The remainder of the heat must be removed through ventilation.

Understanding the basics

Shade on the outside will keep some of the heat out. Shade on the inside, if it contains aluminum foil, will reflect some of the heat back out. Ventilation, either natural or fan, will remove a considerable amount of heat that is collected. Still, on summer days, the temperature may exceed the desired level that promotes good plant growth. Excessive temperature results in delayed flowering and internode stretching. Evaporative cooling may be the best choice under these conditions.

Evaporative cooling is a simple system that uses the heat in the air to evaporate water from leaves and other wetted surfaces. It can cool the greenhouse to 10-20° F below the outside temperature. It takes 1 Btu of heat to raise the temperature of 1 pound of water by 1° F, but it takes 1,060 Btu’s of heat to convert the 1 pound to a vapor.

With an evaporated cooling system, humid air containing the heat that it picked up within the greenhouse is exhausted through the vents or fans to be replaced by cooler, drier outside air. Evaporative cooling works best when the humidity of the outside air is low. For example, in Reno, Nevada, the average summer dry bulb temperature is 96° F and the wet bulb temperature is 61° F. With an evaporative cooler having an efficiency of 80%, the temperature would be cooled to about 68° F. In more humid sections of the U.S., less cooling can occur, but in humid climates like New Orleans where the average summer dry bulb temperature is 93° F and the wet bulb is 78° F, the cooled air would be cooled to about 81°F, which is acceptable for the production of most plants. Fig. 1 shows a comparison of the temperature of cooled air leaving the evaporative cooling system at different relative humidity of the outside air.

Fan and pad system

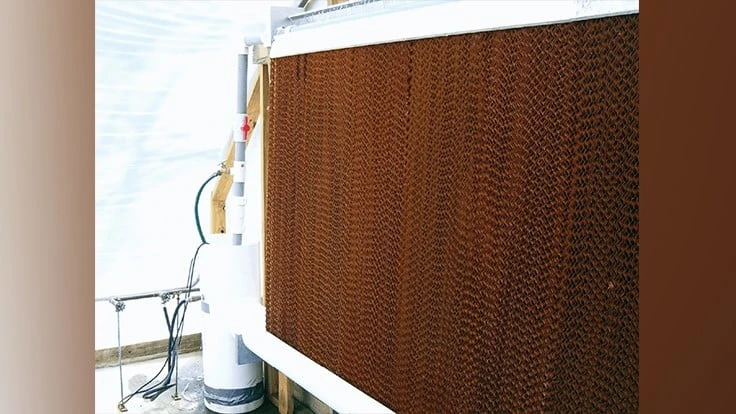

Several evaporative cooling systems work well in commercial greenhouses. The most common is the fan and pad system. It contains a cellulose pad, overhead water supply pipe, gutter to collect excess water, a sump tank, pump, piping and control.

The 4- or 6-inch thick pad is treated with anti-rot salts, stiffening and wetting agents. The pad system is normally installed continuously along the side or end of the wall opposite the fans. The pad area needed is calculated by multiplying the floor area times 8 feet and dividing by 250 for a 4-inch pad or 400 for a 6-inch pad. For example, a 30 x 100-foot greenhouse would require 30 x 100 x 8 ÷ 250 = 96 sq. ft.

The overhead water supply pipe should distribute the water so that the pad is wet uniformly. The minimum water flow rate is ½ gpm/sq. ft. for the 4-inch pad and 0.8 gpm/sq. ft. for the 6-inch pad.

Excess water is collected below the pad in a gutter and piped to a sump tank. Tank capacity needs to be 0.80 gal/sq. ft. of pad for the 4-inch pad and 1.0 gal/sq. ft. for the 6-inch pad. Water returning to the sump should be filtered to remove any debris.

A make-up water supply and float valve keeps the water level constant. In areas that have water with a high mineral content, it is advisable to bleed 3-5% of the water to minimize salt buildup. Algae growth in the recirculated water can be controlled with a biocide.

Modular pad systems of 5 and 6 feet high are available. These are self-contained and come completely assembled ready to bolt to the wall. Installation time is reduced considerably. Only water and electrical connections have to be attached.

Swamp coolers

Self-contained evaporative cooling units, known as “swamp coolers,” consist of a metal enclosure that contains a blower or fan and either cellulose pads and a water pump or a polyester belt that rotates in a pan of water. The dry outside air drawn in through the pads or belt picks up moisture before it enters the greenhouse. After the cool air is heated inside the greenhouse, it is exhausted through the louvers or vents, taking the heat with it. Portable swamp coolers are also available. They are usually placed inside the door, on the end opposite of the fans. They work well in naturally vented greenhouses.

Fog is an alternative evaporative cooling method. Its advantages include more uniform cooling throughout the greenhouse, higher efficiency and lower maintenance costs. It also provides a better method for large gutter-connected greenhouses. This was reviewed in the June 2018 issue of Greenhouse Management (bit.ly/fog-cooling-gm).

Explore the March 2020 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners