At an industry event in New England, Dosatron International Vice President Lela Kelly was discussing water hammer, an issue that occurs in automatic watering systems. “I said to [the audience], ‘How many people here have automatic watering systems with solenoid valves?’ Two people raised their hands,” she says. “I thought maybe they didn’t understand my question. I asked it a different way, and two people raised their hands.”

Growers should recognize the importance of automatic watering systems, Kelly says, and growers who do implement automatic watering systems need to be aware of a common issue — water hammer — and what they can do about it.

The importance of automatic watering

To become or remain profitable, growers should pay attention to several economic factors, Kelly says. One such factor is how much money they are paying employees to water and how much money they could save by automating watering.

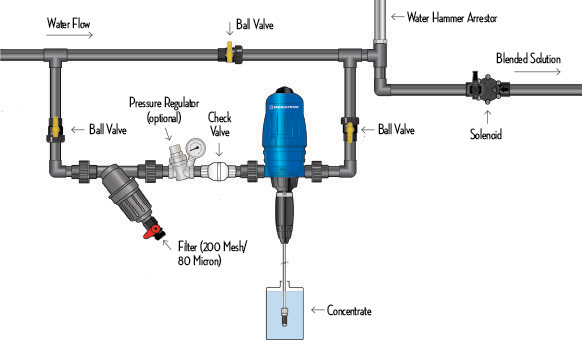

“Any time you do automatic watering, it would be something that would be on drip tubes with a time clock,” she says. “The time clock controls the solenoid valve, turning it on and off automatically.”

Photo courtesy of Lela Kelly

Kelly lists the following disadvantages of manual watering:

- Nonuniform covering of plants and plant parts with water, fertilizer, pesticide or PGR

- Taking the time to individually water many plants

- Having to pay high labor costs to water

- Getting oneself wet or having to wear a raincoat while manually watering hanging baskets

In contrast, she lists the following advantages of automatically watering with drip tubes:

- Uniform covering of plants and plant parts with water, fertilizer, pesticide or PGR

- Having the time to focus on other tasks

- Saving more money on labor

- Avoiding having to manually water hanging baskets and get wet

Recognizing and preventing water hammer

In automatic watering systems, water hammer occurs when a solenoid valve suddenly closes, shooting water back and potentially damaging fertilizer injectors, valve seals or pipes, Kelly says.

“When the water hits that valve that’s closed, it has nowhere to go but backwards, and when it goes backwards, it goes back at three to four times the pressure,” she says. “Let’s say the pressure is 50 PSI [pounds per square inch]. If you multiply that times four, now you have 200 pounds shooting backwards at anything in its way.”

To prevent water hammer, growers should install water hammer arrestors, which Dosatron sells as part of a kit that allows the pressure surge to go right into the arrestor rather than bypassing it.

Water hammer arrestors aren’t usually high-cost, but it depends on the size of the pipe, Kelly says. “If you only have a little three-quarter-inch injector, then maybe you’re spending $120,” she says. “But maybe you’re using a 40-gallon injector, and that 40-gallon injector pricing can be $300 for one. It can be substantial, but fixing an injector can be substantial, and then you have downtime and on and on.”

Growers need to be aware of water hammer, Kelly says, because they might be able to hear rattling in pipes at home, but they can’t hear rattling in PVC pipes they may have in their grow operation. “Water hammer is kind of like a silent killer,” she says.

Explore the October 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Terra Nova Nurseries introduces rust-free and disease-resistant heucherella

- John T. Nickel, founder of Greenleaf Nursery Co., passes away at 89

- Three tours offered at 2025 Farwest Show

- Garden Media Group announces sixth annual Women in Horticulture Week

- Star Roses and Plants announces National Knock Out Rose Day

- The Growth Industry Episode 4: How federal budget cuts are affecting horticulture nonprofits

- The thrips battle plan

- Pennsylvania Horticultural Society shares top gardening trends from 2025 Philadelphia Flower Show