Photo: John W. Bartok Jr.

Mechanizing some of the repetitive tasks associated with transplanting can reduce labor needs and increase production efficiency and capacity. This equipment is available as an integral part of a transplanter line or as separate devices for growers that do hand transplanting.

Tray or pot dispenser

The task of separating flats, pots or inserts is very time consuming. I have watched employees trying to keep up loading pots on a container filling machine. There is always that one pot that is stuck and won’t separate. It is frustrating and sometimes takes as much time to separate the containers as it does to fill them.

To keep up with the average potting machine you must load 2,000 to 4,000 pots per hour. That’s a rate of one pot every one to two seconds.

It may be more difficult to keep up with a flat filler. At an average rate of 20 flats per minute, you must separate the flat from the stack and then separate a sheet of inserts and combine the two. Many growers do this ahead of time because most workers can’t keep up with that pace.

Several equipment manufacturers have developed automatic container separators that feed into a pot or flat filler. A stack of containers is loaded into a tray or holder and fingers pull one container at a time off the stack. They are then fed into the intake of the filler. If inserts are needed, a second device takes care of these. Before purchasing a separator, check to see that the sizes and styles it will handle will match yours.

Dibble

Predibbled flats can save considerable time for transplanters. It can eliminate having to pick up the peg board each time and save five to 10 seconds. A motorized dibble placed on the output end of a container filling machine can do this task easily.

For potting machines, the dibble attaches to the machine and punches or drills the hole just after the pot is filled. The change from one size hole to another takes only a minute or two.

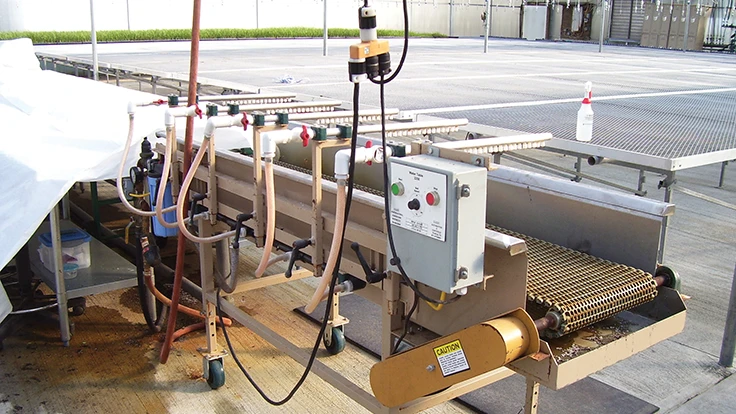

For a flat filling operation, motorized conveyor dibbles were developed. They are powered by a pneumatic or hydraulic cylinder. Adjustable rails guide and position the flats. When a flat moves into position under the dibble, it activates a microswitch or photoeye, which stops the belt momentarily and cycles the dibble.

Watering tunnel

Besides saving considerable time, a watering tunnel can do a more uniform job of wetting the container after it has been transplanted or before it is shipped.

Watering tunnels are mounted above a chain conveyor or perforated, polycarbonate belt that is powered by a variable speed motor. Side panels and a tray or tank below the belt catch excess water and direct it to a drain. A solenoid valve activated by a photoeye or finger switch turns the water on.

Water application rate depends on the type and spacing of the nozzles. Some manufacturers provide several stages to avoid washing out the seedlings or plugs.

You can develop your own tunnel or watering station fairly easily. A simple system consists of a set of water breaker nozzles mounted over the conveyor that takes the containers away from the transplanters. A solenoid valve activates the water supply and a ball valve controls the flow rate.

Tagger

Hand tagging takes from one to six seconds per container. Tagging machines were developed to reduce this time. They usually operate in conjunction with a potting machine, transplanting conveyor or automatic transplanter.

The tagger is usually located over a belt conveyor with the pots or flats passing under one or more tagging heads. The tags are held in a magazine or chute and fed to an insertion head. As the flat or pot comes underneath the head, the container is positioned and a switch stops the belt and the tags are inserted. Most machines insert several tags at a time across a flat.

Compressed air and/or vacuum is needed depending on the manufacturer. Control may be manual or by a preprogrammed solid-state device. With a controller, the flat or pot configuration is entered and the tag chutes positioned. Some machines have a stop signal to indicate when the tag supply runs out. Most machines will handle several styles of insert tags at a rate of at least 500 flats per hour.

The payback on the above devices is fairly short and also allows you to utilize your employees in more productive ways.

Explore the January 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Greenhouse Management

- Anthura acquires Bromelia assets from Corn. Bak in Netherlands

- Top 10 stories for National Poinsettia Day

- Langendoen Mechanical hosts open house to showcase new greenhouse build

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- A legacy of influence

- HILA 2025 video highlights: John Gaydos of Proven Winners